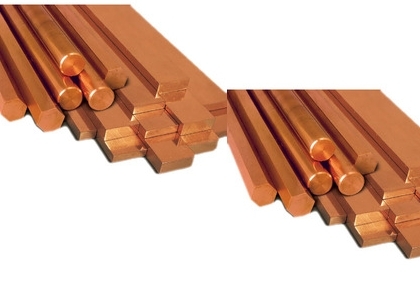

C14500 Telluruim Copper Rod

Product Details:

- Product Type Copper Rod

- Shape Strip

- Grade BS 2874 C 109 EQUIVALENT SPEC. ASTMB C14500

- Click to View more

C14500 Telluruim Copper Rod Price And Quantity

- 1000 INR/Pound

- 250 Pound

C14500 Telluruim Copper Rod Product Specifications

- BS 2874 C 109 EQUIVALENT SPEC. ASTMB C14500

- Strip

- Copper Rod

C14500 Telluruim Copper Rod Trade Information

- 20000 Pound Per Month

- 2-7 Days

Product Description

We offer c14500 telluruim copper rod hold excellent brazing and soldering fabrication technique. It is good for both hot and cold formability. This rod also support resistance arc welding and g shielded arc welding. It finds application in welding and cutting torch tips, transformer and circuit breaker terminals. It is commonly used to produce motor and switch parts, relay parts, furnace brazed parts and screw machine products. This rod holds great electrical and thermal conductivity for electrical switches on power semiconductors. It is also suitable for production of hot forged products. The provided c14500 telluruim copper rod machines very easily and quickly as compare to pure copper.

Typical Applications:

- Gas cutting nozzles

- High-speed automatic screw machines

- Electrical Switches on power semiconductors

- Welding Torch tips

- Transformer & Circuit-breaker terminals

- Fasteners

- Production of hot forged products

| Specifications: | |

| End Product | Specification |

| Bar | ASTM B301 |

| Bar, Forging | ASTM B124 |

| Brazing Filler Metal | FEDERAL QQ-B-650 |

| Fittings | ASME B16.22 |

| Forgings, Die | ASTM B283 |

| Rod | ASTM B301, SAE J461, J463 |

| Rod, Forging | ASTM B124 |

| Shapes | ASTM B301 |

| Shapes, Forging | ASTM B124 |

| Shapes, Refinery | ASTM B216 |

| Wire | ASTM B301 |

| Chemical Composition: | |||

|

| Cu | P | Te |

| Min/Max | 99.90 min | 0.004 - 0.012 | 0.40 - 0.7 |

| Nominals | 99.5 | 0.01 | 0.55 |

| Fabrication: | |

| Joining Technique | Suitability |

| Brazing | Good |

| Butt Weld | Fair |

| Capacity for Being Cold Worked | Good |

| Capacity for Being Hot Formed | Good |

| Coated Metal Arc Welding | Not Recommended |

| Forgeability Rating | 65 |

| Gas Sheilded Arc Welding | Fair |

| Machinability rating | 85 |

| Oxyacetylene Welding | Fair |

| Seam Weld | Not Recommended |

| Soldering | Excellent |

| Spot Weld | Not Recommended |

| Physical Properties: | ||

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 9.5 · 10 6? per °F (68-212 F) | 17.1 · 10 6? per °C (20-100 C) |

| Coefficient of Thermal Expansion | 9.7 · 10 6? per °F (68-392 F) | 17.5 · 10 6? per °C (20-200 C) |

| Coefficient of Thermal Expansion | 9.9 · 10 6? per °F (68-572 F) | 17.8 · 10 6? per °C (20-300 C) |

| Density | 0.323 lb/in3 @ 68 F | 8.94 gm/cm3 @ 20 C |

| Electrical Conductivity | 93 %IACS @ 68 F | 0.544 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 11.2 ohms-cmil/ft @ 68 F | 1.86 microhm-cm @ 20 C |

| Melting Point Liquid US | 1976 F | 1080 C |

| Melting Point Solid US | 1924 F | 1051 C |

| Modulas of Elasticity in Tension | 17000 ksi | 117000 MPa |

| Modulas of Rigidity | 6400 ksi | 44130 MPa |

| Specific Gravity | 8.94 | 8.94 |

| Specific Heat Capacity | 0.092 Btu/lb/°F at 68 F | 393.5 J/kg · °K at 293 K |

| Thermal Conductivity | 205.0 Btu · ft/(hr · Ft2 · °F) at 68 F | 354.8W/m · °K at 20 C |

| Sizes Available: | |

| HOLLOW RODS | Min Bore Size 20 mm and Max OD 100 mm |

| ROUND RODS | 8mm To 100 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

Other Products in 'Copper Rods' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

marketing@shree-extrusion.com

marketing@shree-extrusion.com