IS 8365 CuCrZr Copper Chromium Zirconium

650.00 - 850.00 INR/Kilograms

Product Details:

- Surface Treatment Polished

- Condition New

- Cross Dimension Custom

- Finish Bright / Matt

- Outer Diameter As per drawing/specifications

- Size Customizable

- Diameter Up to 100 mm

- Click to View more

X

IS 8365 CuCrZr Copper Chromium Zirconium Price And Quantity

- 650.00 - 850.00 INR/Kilograms

- 250 Kilograms

IS 8365 CuCrZr Copper Chromium Zirconium Product Specifications

- High tensile strength

- Reddish Brown

- Polished

- Custom

- New

- IS 8365

- Customized or as required

- 80-100 HRB

- Standard/Custom sizes

- As per drawing/specifications

- CuCrZr

- Bright / Matt

- Copper Chromium Zirconium Alloy

- 5 mm Up to 100 mm

- Up to 100 mm

- Plate / Sheet / Rod / Block

- Customizable

IS 8365 CuCrZr Copper Chromium Zirconium Trade Information

- 20000 Kilograms Per Month

- 2-7 Days

Product Description

IS 8365 CuCrZr Copper Chromium Zirconium

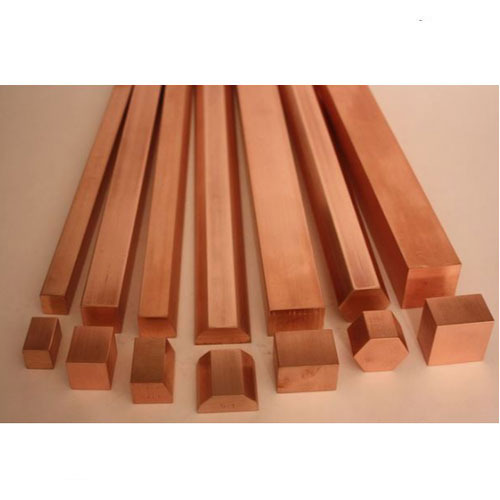

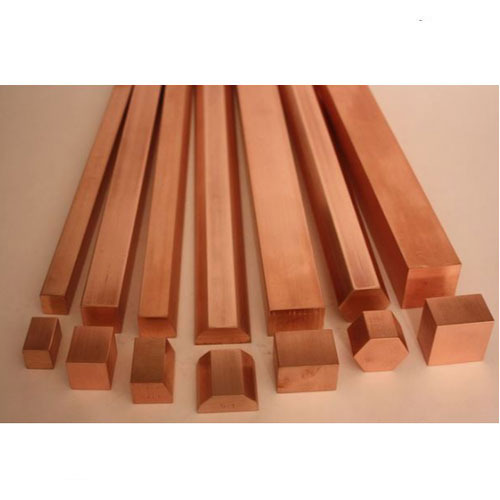

Our company deals in the manufacturing and supplying of IS 8365 CuCrZr Copper Chromium Zirconium which can be used in industries for the production o various industrial grade products such as machine parts, electrical components and architectural elements. It is highly demanding and popular due to its good mechanical and thermal properties. It is available in different sizes with a squared cross sectional areas. The offered IS 8365 CuCrZr Copper Chromium Zirconium can be easily machined with the help of advanced machining technologies.

Superior Performance for Industrial Applications

IS 8365 CuCrZr Copper Chromium Zirconium is engineered for sectors requiring high conductivity, strength, and reliability. Its optimized composition and mechanical properties render it ideal for resistance welding, circuit breakers, and precision moulds. Available in plates, sheets, rods, and blocks with custom dimensions, it assures performance and safety for a wide range of applications.

Precision Manufacturing and Customization

Utilizing state-of-the-art processes such as hot/cold rolling and forging, IS 8365 CuCrZr is manufactured to exacting standards. Each order can be tailored in length, width, thickness, and surface finish, ensuring the alloy matches precise project requirements. The material undergoes polishing for a bright or matt finish, all packaged securely in wooden boxes or cartons for optimal protection during transit.

FAQs of IS 8365 CuCrZr Copper Chromium Zirconium:

Q: How is IS 8365 CuCrZr Copper Chromium Zirconium typically used in industry?

A: This alloy is primarily employed in resistance welding electrodes, circuit breaker devices, and plastic moulds due to its high thermal and electrical conductivity, mechanical strength, and resistance to deformation.Q: What benefits does IS 8365 CuCrZr offer for resistance welding applications?

A: IS 8365 CuCrZr combines high hardness (80-100 HRB) with superior thermal conductivity (290 W/mK), enabling longer electrode life and improved weld quality, while maintaining shape and performance under intense conditions.Q: What manufacturing processes are used for producing IS 8365 CuCrZr Copper Chromium Zirconium?

A: The alloy is produced through advanced hot/cold rolling and forging methods. These processes allow for customizable shapes and dimensions, ensuring precise fit and structural integrity for various industrial uses.Q: When can customers expect delivery of IS 8365 CuCrZr products?

A: Lead times for IS 8365 CuCrZr products range from 2 to 4 weeks, depending on order complexity and customization requirements.Q: Where does distribution and supply for IS 8365 CuCrZr take place?

A: IS 8365 CuCrZr is distributed, exported, and supplied throughout India by reputable manufacturers, distributors, traders, and service providers.Q: What packaging is provided to ensure product safety during transit?

A: Products are packed in sturdy wooden boxes or cartons, guaranteeing safe delivery and protection from physical or environmental damage.Q: How can one customize the dimensions and finish for IS 8365 CuCrZr orders?

A: Custom sizes in length, width, thickness, and cross dimensions are available as per drawings or specifications, with the choice of bright or matt polished finishes to meet individual application requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com