C27450 DZR Lead Free Brass

480 INR/Kilograms

Product Details:

- Type Forging and Machining Grade Brass Rod

- Material Lead Free Brass

- Grade C27450

- Tolerance +0.1mm / -0.1mm

- Alloy C27450 DZR

- Temper HD (Half Hard), H (Hard), Y2

- Length 2 Meter to 5 Meter

- Click to View more

X

C27450 DZR Lead Free Brass Price And Quantity

- 450.00 - 500.00 INR/Kilograms

- 250 Kilograms

- 480 INR/Kilograms

C27450 DZR Lead Free Brass Product Specifications

- Forging and Machining Grade Brass Rod

- 8mm to 90mm

- Round, Hex, Square, Flat

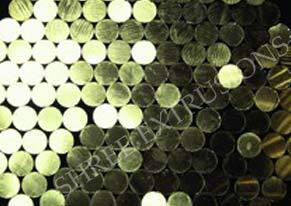

- Golden Yellow

- As per size and order requirement

- 2 Meter to 5 Meter

- C27450 DZR

- +0.1mm / -0.1mm

- C27450

- HD (Half Hard), H (Hard), Y2

- Lead Free Brass

C27450 DZR Lead Free Brass Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

Eco Brass / DZR Brass (Dezincification Resistant Brass)

Equivalent Specifications :

| Specifications | Designation |

| ISO | CuZn37 |

| Europen | CW508L |

| BS | |

| JIS | C27450 |

| Russian |

C27450 Lead Free Brass to not only aid in lead free compliance, but to optimize manufacturing efficiencies through productivity & complete recyclability.

Typical Applications :

- Potable water components, fixtures & applications

- PEX plumbing applications & systems

- Forged products requiring lead free &/or dezincification compliance

Advantages :

- Good machinability

- Excellent forgeability

- Excellent ability to Thread Roll

- Excellent Brazing & Plating

- Dezincification Resistant

| Cu | Pb | Fe | Zn | Others | |

| Min/Max | 60-65 | <0.25 (max) | 0.35 | Rem | <0.5 |

| Nominals | 63.00 | 37.00 |

Mechanical Properties

| Rod H02 | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Hardness (Rb) |

| 58 | 40 | 30% | 55-75 |

Fabrication Properties

| Soldering | Excellent |

| Brazing | Excellent |

| Cold working | Excellent |

| Plating | Excellent |

| Forgability | 95 |

| Machinability | 70 |

Sizes Available

| WIRE | 1mm TO 8 mm |

| HOLLOW RODS | Min Bore Size 20 mm and Max OD 100 mm |

| ROUND RODS | 6mm To 130 mm |

| HEX | 5mm To 60mm |

| SQUARE | 4mm To 60mm |

| FLAT | 5mm Min Thickness and max Width 120mm |

| PROFILES / SECTIONS | AS per Customer Drawing |

| BILLETS | Up to 200mm |

| INGOTS | AS per Specification |

Superior Dezincification Resistance

C27450 DZR Lead Free Brass offers outstanding protection against dezincification, ensuring structural integrity in harsh water environments. The alloy design minimizes zinc loss, making it ideal for critical plumbing and potable water systems. With compliance to NSF/ANSI 61, it guarantees safety for drinking water applications.

Versatile Applications and Customization

Renowned for its flexibility, C27450 DZR brass is crafted in various shapes including round, hex, square, and flat, and is available in multiple tempers. This makes it a preferred material for valves, fittings, marine components, and plumbing systems. Tailored lengths, diameters, and packaging are provided according to order specifications.

FAQs of C27450 DZR Lead Free Brass:

Q: What are the main benefits of using C27450 DZR Lead Free Brass for potable water systems?

A: C27450 DZR Lead Free Brass offers high corrosion resistance, excellent machinability, and full compliance with NSF/ANSI 61. Its low lead content (<0.25%) ensures water safety, while its dezincification-resistant properties maintain integrity in water-contact applications.Q: How is C27450 DZR brass typically processed for use in manufacturing industries?

A: This alloy is supplied as forging and machining grade brass rods, in sizes ranging from 8mm to 90mm in diameter. It is processed through precision forging or machining to meet specific requirements, with customizable shapes and lengths provided as per order.Q: When should C27450 DZR Lead Free Brass be chosen over standard brass alloys?

A: Select C27450 DZR when dezincification resistance, low lead content, and compliance with potable water standards are crucialparticularly in plumbing, marine, and valve applications where longevity and water quality are priorities.Q: Where can this alloy be utilized beyond plumbing systems?

A: Apart from plumbing, C27450 DZR is widely used in marine environments, valves, fittings, and other components exposed to moisture or high corrosion risk, thanks to its durability and non-toxic composition.Q: What is the manufacturing process for C27450 DZR brass rods?

A: The manufacturing involves melting high-grade raw materials, alloying to achieve specific properties, and casting into rods. Subsequent hot or cold working produces smooth, burr-free, and mechanically robust rods ready for forging or machining.Q: How does the bright/polished finish of C27450 DZR brass enhance its application?

A: The bright or polished finish not only improves the aesthetic appeal but also provides a smooth, burr-free surface, reducing the risk of contamination and making the rods ideal for visible or hygiene-sensitive installations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Leaded Brass' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com