C34500 High Leaded Brass

Product Details:

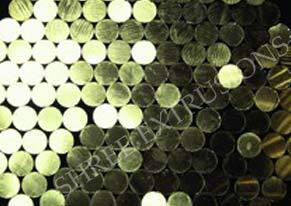

- Type High Leaded Brass Rod

- Material Brass

- Grade C34500

- Tolerance 0.05 mm

- Alloy C34500

- Temper Half Hard

- Length As per requirement (typically 500mm to 3000mm)

- Click to View more

C34500 High Leaded Brass Price And Quantity

- 450.00 - 500.00 INR/Kilograms

- 480 INR/Kilograms

- 250 Kilograms

C34500 High Leaded Brass Product Specifications

- High Leaded Brass Rod

- C34500

- 0.05 mm

- 3 mm to 75 mm

- Based on rod dimensions

- Round Rod

- Half Hard

- Brass

- C34500

- Yellow Golden

- As per requirement (typically 500mm to 3000mm)

C34500 High Leaded Brass Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

By keeping track of the current market developments, we are involved in manufacturing, exporting and supplying C34500 High Leaded Brass. This brass is used for armor in the outer walls and roofs of different architectural structures. Our offered brass is made available with us in numerous thickness, lengths and finishes. The provided brass is manufactured by our adroit professionals using superlative quality copper and zinc with the help of superior manufacturing techniques. Further, clients can avail this C34500 High Leaded Brass at market leading rates.

Features:

-

Durability

-

Corrosion resistance

-

Perfect finish

-

Stress crack proof

C34500 high leaded brass "64%" is the brass with high machining ability. The increase in lead content will result in increased machining ability with good strength and atmospheric corrosion resistance. The increased lead content will also provide pressure tightness by sealing the shrinkage pores.

Applications :

- Industrial : Pinions, Gears, Valve Stems, Flare Fittings, Adapters, Couplings

- Plumbing: Plumbing Fittings, Plumbers' Brass Goods

Equivalent Specifications:

| CATEGORY / STANDARD | ASTM | BS | EN | JIS | DIN | ISO |

| High Leaded Brass | C34500 | CZ131 | CW601N | C3560 |

| CuZn34Pb2 |

| Specifications | Designation |

| ISO | CuZn34Pb2 |

| Europen | CuZn35Pb2 |

| JIS | C3560 |

| Russian | LS63-2 |

Chemical Composition:

|

| Cu | Fe | Pb | Zn |

| Min/Max | 59.0-63.0 | 0.07 | 0.3 | Rem |

| Nominals | 60000 | -0 | -0 | 40 |

Specification

| End Product | Specification |

| Bar | ASTM B36 |

| Wire | ASTM B36 |

| Rods | ASTM B36 |

| Ingots | ASTM B36 |

| Tube, Condenser | ASME SB111, ASTM B111 |

| Tube, Seamless | ASTM B135, FEDERAL WW-T-791 |

| Fabrication: | |

| Joining Technique | Suitability |

| Brazing | Excellent |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Fair |

| Capacity for Being Hot Formed | Excellent |

| Coated Metal Arc Welding | Not Recommended |

| Forgeability Rating | 90 |

| Gas Sheilded Arc Welding | Fair |

| Machinability rating | 40 |

| Oxyacetylene Welding | Good |

| Seam Weld | Not Recommended |

| Soldering | Excellent |

| Spot Weld | Good |

Physical Properties:

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 11.6 10-6 per oF (68-572 F) | 20.9 C (20-300 C) |

| Density | 0.303 lb/in3 @ 68 F | 8.39 gm/cm3 @ 20 C |

| Electrical Conductivity | 28 %IACS @ 68 F | 0.164 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 37.0 ohms-cmil/ft @ 68 F | 6.15 microhm-cm @ 20 C |

| Melting Point Liquid US | 1660 F | 904 C |

| Melting Point Solid US | 1650 F | 899 C |

| Modulas of Elasticity in Tension | 15000 ksi | 103400 MPa |

| Modulas of Rigidity | 5600 ksi | 38610 MPa |

| Specific Gravity | 8.39 | 8.39 |

| Specific Heat Capacity | 0.09 Btu/lb/F @ 68 F | 377.1 J/kg K at 293 K |

| Thermal Conductivity | 71.0 Btu ft/(hr F) @ 68 F | 1229.9 W/m K at 20 C |

Size Available

| WIRE | 1mm TO 8 mm |

| HOLLOW RODS | Min Bore Size 20 mm and Max OD 100 mm |

| ROUND RODS | 6mm To 130 mm |

| HEX | 5mm To 60mm |

| SQUARE | 4mm To 60mm |

| FLAT | 5mm Min Thickness and max Width 120mm |

| PROFILES / SECTIONS | AS per Customer Drawing |

| BILLETS | Up to 200mm |

| INGOTS | AS per Specification |

Exceptional Machinability and Strength

With a machinability rating of 90%, C34500 High Leaded Brass allows precise and consistent machining, minimizing tool wear for manufacturers. Its minimum tensile strength of 340 MPa and elongation of at least 15% ensure both durability and effective deformation resistance, crucial for demanding applications in various industries.

Versatile Industrial Applications

Engineered for use in automotive, electrical, marine, and plumbing sectors, this alloys excellent corrosion resistance and smooth bright finish enable reliable use in environments facing moisture and wear. Round rods are available in half-hard temper, making them adaptable to specific performance requirements.

FAQs of C34500 High Leaded Brass:

Q: How is C34500 High Leaded Brass processed for industrial use?

A: C34500 is manufactured into round rods with half-hard temper, typically offered in lengths of 500mm to 3000mm and diameters from 3mm to 75mm. The alloy undergoes precise casting, extrusion, and finishing processes to achieve smooth surfaces and tight dimensional tolerances (0.05 mm), meeting ASTM B16/B16M-10 standards.Q: What benefits does the high lead content provide in C34500 brass rods?

A: The lead content of 2.5%3.5% greatly improves machinability, rated at 90%, allowing easier cutting, drilling, and forming. This results in faster production, lower manufacturing costs, and finer surface finishes, making it a preferred choice for precision components.Q: Where are C34500 High Leaded Brass rods commonly used?

A: These rods are widely utilized in automotive, electrical, marine, and plumbing industries. Their good corrosion resistance and high machinability make them suitable for manufacturing connectors, fittings, valves, and components exposed to aggressive environments.Q: When should C34500 High Leaded Brass be selected over other brass alloys?

A: Choose C34500 when excellent machinability, bright finish, and dependable mechanical properties are required, especially for intricate parts or components needing precise shaping and durable performance in critical applications.Q: What is the export packing process for C34500 High Leaded Brass rods?

A: For global shipment, rods are packed in standard export-worthy bundles or tailored packaging as per specific requirements. This ensures product integrity, prevents damage during transit, and meets international shipping standards.Q: How does the corrosion resistance of C34500 brass impact its usage?

A: Its good corrosion resistance supports usage in marine, plumbing, and outdoor electrical components, prolonging service life and maintaining integrity in environments exposed to moisture, chemicals, or varying temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leaded Brass' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com