C36000 Free Machining Brass

Product Details:

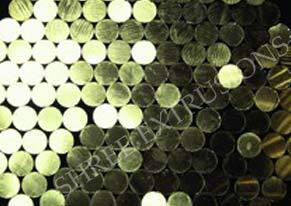

- Type Round Bar

- Material Brass

- Grade Free Machining Brass

- Tolerance h9

- Alloy C36000

- Temper Half Hard

- Length 1 Meter

- Click to View more

C36000 Free Machining Brass Price And Quantity

- 450.00 - 500.00 INR/Kilograms

- 480 INR/Kilograms

- 250 Kilograms

C36000 Free Machining Brass Product Specifications

- C36000

- Round Bar

- 1 Meter

- h9

- Half Hard

- Free Machining Brass

- 6 mm 100 mm

- Round

- Varies as per size

- Golden Yellow

- Brass

C36000 Free Machining Brass Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

We are a desirable manufacturer, exporter and supplier of superlative quality gamut of C36000 Free Machining Brass that is suitable for various architectural products, industrial components and many more. Widely appreciated due to its ruggedness, this brass is made available for clients in different lengths and thicknesses to meet the wide requirements of clients. The offered brass is manufactured using top-notch grade copper and zinc under the stern vigilance of skilled our professional. Further, the offered C36000 Free Machining Brass can be purchased from us at cost-effecting prices.

Features:

-

Robustness

-

Corrosion resistance

-

Perfect finish

-

Durable

C36000 Free Machining Brass is also called Free Cutting Brass. The brass is appreciated for features such as knurling, thread rolling and good machining ability. It is deal for high machining operations with the rating of 100 against all the rated copper alloys. The offered brass can easily be brazed or soldered and is also corrosion resistant.

Applications :

- Construction Industry: Builders Hardware, Lock Bodies, Hardware, Fittings

- Consumer: Hot Combs (to Straighten Hair)

- Fasteners: Bolts, Nuts, Screws

- Industrial: Faucet Components, Pneumatic Fittings, Fluid Connectors, Automatic Screw Machine Parts, Unions, Adapters, Screw Machine Products, Gauges, Valve Seats, Valve Trim, Valve Stems, Nozzles, Pinions, Gears

- Plumbing: Plumbers' Brass Goods, Faucet Stems, Faucet Seats, Plumbing Fittings

| Equivalent Specifications: | |

| Specifications | Designation |

| ISO | CuZn36Pb3 |

| Europen | CuZn36Pb3 |

| JIS | CZ-124 |

| Russian | LS63-3 |

| Chemical Composition: | ||||

|

| Cu | Fe | Pb | Zn |

| Min/Max | 60.0 - 63.0 | 0.35 | 2.5 - 3.7 | Rem |

| Nominals | 61.5 | - | 3.1 | 35.4 |

| Specifications: | |

| End Product | Specification |

| Bar | AMS 4610, ASTM B16, SAE J461, J463 |

| Rod | AMS 4610, ASTM B16, SAE J461, J463 |

| Shapes | ASTM B16, SAE J461, J463 |

| Valves | MILITARY MIL-V-18436 |

| Wire | ASTM B16 |

| Fabrication: | |

| Joining Technique | Suitability |

| Brazing | Good |

| Butt Weld | Fair |

| Capacity for Being Cold Worked | Fair |

| Capacity for Being Hot Formed | Fair |

| Coated Metal Arc Welding | Not Recommended |

| Gas Sheilded Arc Welding | Not Recommended |

| Machinability rating | 100 |

| Oxyacetylene Welding | Not Recommended |

| Seam Weld | Not Recommended |

| Soldering | Excellent |

| Spot Weld | Not Recommended |

| Physical Properties: | ||

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 11.4 ·10-6 per oF (68-572 F) | 20.5°C (20-300 C) |

| Density | 0.307 lb/in3 @ 68 F | 8.5 gm/cm3 @ 20 C |

| Electrical Conductivity | 26 %IACS @ 68 F | 0.152 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 39.9 ohms-cmil/ft @ 68 F | 6.63 microhm-cm @ 20 C |

| Melting Point Liquid US | 1650 F | 899 C |

| Melting Point Solid US | 1630 F | 888 C |

| Modulas of Elasticity in Tension | 14000 ksi | 96500 MPa |

| Modulas of Rigidity | 5300 ksi | 36500 MPa |

| Specific Gravity | 8.5 | 8.5 |

| Thermal Conductivity | 67.0 Btu ft2 °F) @ 68 F | 116.0 W/m °K at 20 C |

| Sizes Available | |

| WIRE | 1mm TO 8 mm |

| HOLLOW RODS | Min Bore Size 20 mm and Max OD 100 mm |

| ROUND RODS | 6mm To 130 mm |

| HEX | 5mm To 60mm |

| SQUARE | 4mm To 60mm |

| FLAT | 5mm Min Thickness and max Width 120mm |

| PROFILES / SECTIONS | AS per Customer Drawing |

| BILLETS | Up to 200mm |

| INGOTS | AS per Specification |

Exceptional Machinability

C36000 Free Machining Brass delivers unmatched machinability, rated at 100%, making it a top choice for high-precision parts. The alloys properties allow for smooth, swift cutting, reducing tool wear and enhancing production efficiency. This makes it highly appealing for manufacturers focusing on consistent, high-volume output.

Consistent Quality and Performance

Manufactured to ASTM B16 standards, each round bar of C36000 brass ensures reliable mechanical characteristics. With a minimum tensile strength of 345 MPa and a yield strength of 125 MPa, the material is trusted for durability and uniformity, critical for engineering and automotive applications.

Versatile Applications and Availability

The C36000 Free Machining Brass is supplied in diameters ranging from 6 mm to 100 mm, making it highly adaptable for varied uses. As a distributor, exporter, and supplier based in India, we offer this alloy with precise tolerances in round bar form, ideal for a variety of industries seeking golden yellow, corrosion-resistant brass.

FAQs of C36000 Free Machining Brass:

Q: How is C36000 Free Machining Brass processed for precision components and automotive parts?

A: The alloy is supplied as round bars with tight h9 tolerance and bright finish, allowing easy turning, drilling, and milling. Its half-hard temper ensures form stability during machining, making it ideal for precision engineering and auto parts manufacturing.Q: What are the key benefits of choosing C36000 Free Machining Brass for engineering purposes?

A: C36000 offers superior machinability (100%), strength, and elongation, minimizing tool wear and production time while delivering consistent, high-quality results for intricate engineering applications.Q: When should I select C36000 Free Machining Brass over other brass types?

A: Opt for C36000 when high-speed machining and fine tolerances are required, such as in mass-produced precision components where efficiency, surface finish, and dimensional accuracy are critical.Q: Where is this brass grade commonly used in industry?

A: C36000 Free Machining Brass is extensively used in the manufacture of auto parts, electrical fittings, precision engineering components, and mechanical assemblies demanding high dimensional accuracy.Q: What is the recommended process for handling and machining C36000 round bars?

A: Handle the bars using appropriate supports to prevent bending. Employ carbide or high-speed steel tools for machining, as the alloy allows for rapid feed rates and produces minimal burr, ensuring efficient workflow.Q: How does the machinability rating of 100% impact the manufacturing process?

A: The top machinability rating enables faster cutting speeds, reduced tooling costs, and improved surface finishes. It streamlines large-scale production, increases throughput, and ensures less downtime for tool changeovers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leaded Brass' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com