C95900 ALUMINUM BRONZE

Product Details:

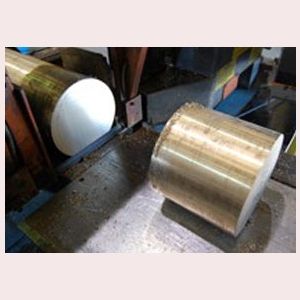

- Technique Casting

- Temper As Cast

- Product Type Aluminum Bronze Bars

- Material Aluminum Bronze

- Alloy C95900

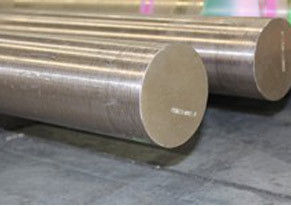

- Shape Round Bars, Flats, Plates

- Dimension (L*W*H) Custom as per requirement

- Click to View more

C95900 ALUMINUM BRONZE Price And Quantity

- 480 INR/Kilograms

- 250 , , Kilograms

- 450.00 - 500.00 INR/Kilograms

C95900 ALUMINUM BRONZE Product Specifications

- Golden Yellow

- Bushings, Bearings, Marine Hardware, Industrial Components

- C95900

- Custom as per requirement

- Aluminum Bronze

- Casting

- Round Bars, Flats, Plates

- As Cast

- Aluminum Bronze Bars

- Depend on Size

C95900 ALUMINUM BRONZE Trade Information

- 20000 , , Kilograms Per Month

- 4 Week

Product Description

C95900 ALUMINUM BRONZE

C95900 Aluminum Bronze is characterized by its high strength and excellent corrosion resistance. Uses for the alloy include a variety of heavy duty mechanical and structural products including gears, worm drives, valve guides and seats. C95900 is an excellent heavy duty bearing alloy, but does not tolerate misalignment or dirty lubricants and generally should be used against hardened steel shafts, with both shaft and bearing machined to fine surface finishes.

Typical Uses: Industrial: Gears, worm drives

Sizes Available :

| ROUND RODS | 8mm To 70 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

CHEMICAL COMPOSITION

|

| Al | Cu | Fe | Mn | Ni |

| Min/Max | 12.0-13.5 | Rem. | 3.0-5.0 | 1.5 | 0.5 |

| Nominals | 12.7000 | - | 4.0000 | - | - |

SPECIFICATIONS

| End Product | Specification |

| Centrifugal | ASTM B271 |

| Continuous | ASTM B505 |

| Ingot | ASTM B30 |

| Sand | ASTM B148 |

Physical Properties*

| Density (lbs/in3) | .260 |

| Specific Gravity | 7.21 |

| Specific Heat | .09 |

| Coefficient of Thermal Expansion | 9.0 x 10-6 |

| Electrical Conductivity | 10 |

| Electrical Resistivity (Microhms-Meter @ 680F) | 172 |

| Thermal Conductivity | 22.5 |

| Magnetic Permeability | 1 |

Superior Performance in Harsh Environments

C95900 Aluminum Bronze excels in demanding applications due to its robust mechanical properties and outstanding corrosion resistance. Ideal for marine and industrial atmospheres, it provides reliability where other materials may falter, ensuring longevity and reduced maintenance costs for critical components.

Versatile Applications & Customization

This alloy is commonly used in bushings, bearings, marine hardware, and industrial components. Offered in round bars, flats, or plates, and available in custom sizes, C95900 Aluminum Bronze gives engineers the flexibility to meet specific design requirements for diverse industry projects.

FAQs of C95900 ALUMINUM BRONZE:

Q: How is C95900 Aluminum Bronze manufactured?

A: C95900 Aluminum Bronze is primarily produced using the casting technique, which allows for precise shaping into round bars, flats, or plates. This method ensures consistent quality and mechanical properties suitable for critical industrial applications.Q: What benefits does C95900 Aluminum Bronze offer in marine environments?

A: This alloy provides excellent corrosion resistance, making it ideal for marine hardware, bushings, and bearings exposed to seawater and harsh atmospheres. Its durability helps ensure longer service life and minimal maintenance.Q: When should I consider using C95900 Aluminum Bronze for my project?

A: Choose C95900 Aluminum Bronze when you require components with high tensile and yield strength, good toughness, and outstanding resistance to corrosionespecially in marine or industrial settings. It is best suited for applications where reliability and longevity are essential.Q: Where is C95900 Aluminum Bronze commonly applied?

A: C95900 Aluminum Bronze is widely utilized in bushings, bearings, marine hardware, and various industrial components due to its mechanical strength and corrosion resistance. Its adaptability to custom dimensions also makes it popular in specialized manufacturing environments.Q: What is the machinability of C95900 Aluminum Bronze?

A: This alloy offers fair to good machinability, allowing for efficient shaping and finishing during fabrication. Its hardness range (Rockwell B100 C29) ensures components maintain dimensional stability while permitting workable processing during machining.Q: What is the process for ordering C95900 Aluminum Bronze in custom sizes?

A: Customers can specify their required dimensions for round bars, flats, or plates when placing orders. As the alloy is cast to order, manufacturers and suppliers in India can provide tailored solutions to fit unique engineering or production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminium Bronze' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com