C62400 ALUMINUM BRONZE

Product Details:

- Temper Hard

- Technique Hot Rolled

- Product Type Metal Alloys

- Material Aluminum Bronze

- Alloy C62400

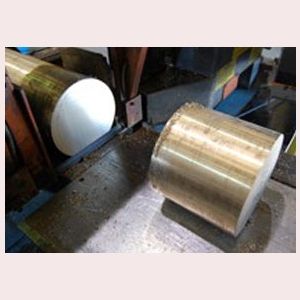

- Shape Round

- Dimension (L*W*H) Customized

- Click to View more

C62400 ALUMINUM BRONZE Price And Quantity

- 450.00 - 500.00 INR/Kilograms

- 250 , , Kilograms

- 480 INR/Kilograms

C62400 ALUMINUM BRONZE Product Specifications

- Golden

- Aluminum Bronze

- Metal Alloys

- C62400

- Hot Rolled

- Hard

- Round

- Industrial

- Customized

- Customized

C62400 ALUMINUM BRONZE Trade Information

- 20000 , , Kilograms Per Month

- 4 Week

Product Description

C62400 ALUMINUM BRONZE

The aluminum bronze C62300 and C62400 is used while manufacturing valve and pump components for industrial process streams, marine equipment, high strength fasteners and pole line hardware.

Applications :-

Fasteners : Nuts, Bolts

Industrial : Gears, Bearing Races, Valve Stems, Worm Gears, Valve Guides, Valve Seats, Bearings, Bushings, Cams, Pump Rods

Marine: Marine Hardware

Chemical Composition:

|

| Al | Cu | Fe | Mn | Si | Sn |

| Min (%) | 10.0 - 11.5 | Rem | 2.0 - 4.5 | 0.3 | 0.25 | 0.2 |

| Max (%) | 11.0000 | 86.0000 | 3.0000 | - | - | - |

Specifications :

| End Product | Specification |

| Forgings | SAE J463, J461 |

| Rod | ASTM B150 |

| Rod, Welding | AWS A5.7 |

Fabrication:

| Joining Technique | Suitability |

| Brazing | Fair |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Poor |

| Capacity for Being Hot Formed | Excellent |

| Coated Metal Arc Welding | Good |

| Forgeability Rating | 80 |

| Gas Sheilded Arc Welding | Good |

| Machinability rating | 50 |

| Oxyacetylene Welding | Not Recommended |

| Seam Weld | Good |

| Soldering | Not Recommended |

| Spot Weld | Good |

Physical Properties

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 9.0 ·10-6 per oF (68-572 F) | 16.2 10 6? per C (20-300 C) |

| Density | 0.269 lb/in3 at 68 F | 7.45 gm/cm3 @ 20 C |

| Electrical Conductivity | 12 %IACS @ 68 F | 0.07 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 86.4 ohms-cmil/ft @ 68 F | 14.36 microhm-cm @ 20 C |

| Melting Point Liquid US | 1900 F | 1038 C |

| Melting Point Solid US | 1880 F | 1027 C |

| Modulas of Elasticity in Tension | 17000 ksi | 117000 MPa |

| Modulas of Rigidity | 6400 ksi | 44130 MPa |

| Specific Gravity | 7.45 | 7.45 |

| Specific Heat Capacity | 0.09 Btu/lb/°F @ 68 F | 377.1 J/kg °K at 293 K |

| Thermal Conductivity | 34.0 Btu ft/(hr · ft2 F) @ 68 F | 58.8 W/m °K at 20 C |

Sizes Available

| ROUND RODS | 8mm To 70 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

Outstanding Mechanical Properties and Durability

C62400 Aluminum Bronze stands out for its robust mechanical properties, including high tensile strength and impressive elongation. Its hardness rating of 150-190 HB ensures it can withstand demanding industrial stresses, while the excellent corrosion resistance makes it suitable even for harsh operating environments. This exceptional combination makes it a chosen material for components that require both longevity and reliability.

Versatile Forms and Finishes for Industrial Use

Available in customizable rod, bar, or tube forms, C62400 Aluminum Bronze can be tailored to specific industrial needs. The hot rolled technique paired with a polished surface finish enhances durability and visual appeal. Manufacturers, distributors, and suppliers across India offer this versatile alloy in a range of shapes and sizes, ensuring compatibility with a wide variety of engineering applications.

Performance Benefits in Your Application

With its unique blend of conductivity, machinability, and hardness, C62400 is widely used for components subjected to heavy wear and corrosive conditions, such as bushings, bearings, and marine hardware. Its golden color and polished finish provide an aesthetic edge, making it both functional and visually appealing for demanding environments.

FAQs of C62400 ALUMINUM BRONZE:

Q: How is C62400 Aluminum Bronze typically processed and formed?

A: C62400 Aluminum Bronze is produced using the hot rolling technique, which imparts high strength and ensures consistent quality. It can be customized into rods, bars, or tubes with polished surfaces, meeting various dimensional requirements for industrial applications.Q: What benefits does C62400 Aluminum Bronze offer for industrial applications?

A: C62400 Aluminum Bronze provides excellent corrosion resistance, good machinability, and high tensile strength, making it ideal for use in environments exposed to harsh chemicals or mechanical stress, such as marine, chemical processing, and heavy machinery industries.Q: When should I choose C62400 Aluminum Bronze over other alloys?

A: You should consider C62400 when your project demands a combination of superior strength, outstanding corrosion resistance, and moderate conductivity. It is especially preferred in applications involving friction, seawater exposure, or heavy mechanical loads.Q: Where is C62400 Aluminum Bronze most commonly used?

A: This alloy is widely utilized in industries across India for manufacturing bearings, bushings, gears, marine components, and parts subjected to corrosive or high-wear environments. It is distributed, exported, and supplied by specialized manufacturers and traders throughout the region.Q: What are the main advantages of the polished finish on C62400 Aluminum Bronze products?

A: The polished surface finish not only enhances the aesthetic appeal of C62400 but also provides additional protection against corrosion and wear, extending the service life and reliability of components in demanding settings.Q: How does the machinability of C62400 Aluminum Bronze benefit manufacturers?

A: C62400 offers good machinability, allowing for precise shaping and fabrication with reduced tool wear. This leads to efficient production processes, improved surface finishes, and lower manufacturing costs for complex parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminium Bronze' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com