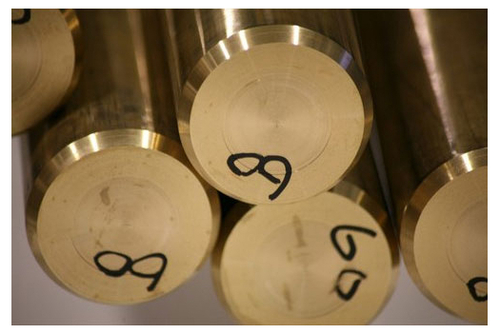

CC762S High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CC762S

- Tolerance 0.05 mm

- Alloy CC762S

- Temper Hard / Half Hard / Annealed

- Length 3 m to 6 m (customizable)

- Click to View more

CC762S High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CC762S High Tensile Brass Rods Product Specifications

- Yellowish Golden

- 5 mm to 100 mm

- High Tensile Brass Rod

- 3 m to 6 m (customizable)

- Brass

- 0.05 mm

- Round / Hex / Square

- CC762S

- CC762S

- Variable as per size

- Hard / Half Hard / Annealed

CC762S High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CC762S High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Wide Range of Industrial Applications

Designed for use in marine, automotive, and engineering sectors, CC762S High Tensile Brass Rods are built to endure harsh environments and heavy-duty operations. Their excellent corrosion resistance and strength make them ideal for components exposed to moisture, pressure, and dynamic loads. The rods versatility allows them to be easily adapted to various custom industrial requirements.

Superior Performance and Customization

Every CC762S Brass Rod is manufactured following strict quality standards to guarantee superior mechanical properties like high tensile strength and good elongation. Available in different tempers and finishes (bright, polished, smooth), we offer extensive customizationchoose rounds, hexes, or squares, and specify length and diameter as needed. Each order is securely packed for safe export and delivery.

FAQs of CC762S High Tensile Brass Rods:

Q: How are CC762S High Tensile Brass Rods typically used in different industries?

A: CC762S High Tensile Brass Rods find applications in marine, automotive, and engineering industries due to their strength, corrosion resistance, and workability. They are utilized for making machine parts, fasteners, valves, connectors, and structural components where durability and high performance are essential.Q: What is the manufacturing process for these brass rods?

A: The manufacturing process involves melting high-quality brass, alloyed to the CC762S specification, then casting, hot rolling, and precise extrusion into the desired shapes and sizes. Final treatments include tempering (hard, half hard, annealed) and finishing (bright, polished, or smooth surfaces) to meet strict tolerances and customer requirements.Q: When should I select the hard, half hard, or annealed temper brass rods?

A: The choice of temper depends on your applications mechanical demands. Hard temper is ideal for maximum strength, half hard offers moderate balance, and annealed is best for parts needing superior formability without cracking. Consulting the mechanical requirements of the end-use will guide the appropriate selection.Q: Where can customized CC762S Brass Rods be sourced?

A: These rods are available directly from distributors, exporters, manufacturers, and suppliers based in India. Customization in terms of length, diameter, shape, and finishes can be discussed during ordering to ensure the rods match project requirements precisely.Q: What are the main benefits of using CC762S brass alloy for rods?

A: The CC762S brass alloy provides an optimal mix of high tensile strength, excellent machinability, and superior corrosion resistance. These attributes ensure the rods are reliable and durable for critical applications, reducing maintenance costs and increasing longevity.Q: How is the quality and dimensional accuracy of these rods ensured?

A: Each rod is manufactured to international standards (IS 319 / BS 2874) and adheres to strict tolerance controls of 0.05 mm. Regular inspections and testing are performed during and after production to guarantee consistent quality, strength, and precise dimensions.Q: What packaging process is used for exporting CC762S High Tensile Brass Rods?

A: To prevent damage during transit, rods are packed in standard export-worthy packaging, often using sturdy wooden cases, bundles, or protective wrapping, ensuring they arrive safely and in optimal condition to clients worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com