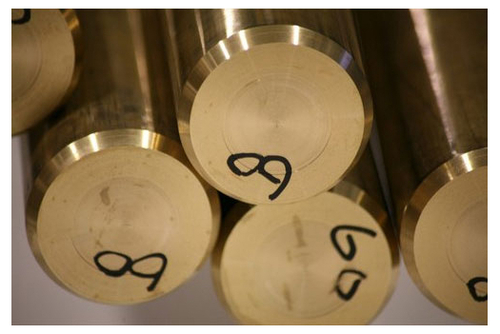

2.055 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade 2.055 (CZ112)

- Tolerance 0.02 mm

- Alloy 2.055

- Temper Hard / Half Hard / Quarter Hard

- Length 3 to 6 meters

- Click to View more

2.055 High Tensile Brass Rods Price And Quantity

- 250 Kilograms

- 350.00 - 450.00 INR/Kilograms

2.055 High Tensile Brass Rods Product Specifications

- 0.02 mm

- Hard / Half Hard / Quarter Hard

- 2.055

- 2.055 (CZ112)

- Golden Yellow

- 5 mm to 100 mm

- Brass

- Varies with size and length

- Round, Hex, Square

- 3 to 6 meters

- High Tensile Brass Rod

2.055 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

2.055 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

High Performance and Precision Tolerance

Our 2.055 High Tensile Brass Rods deliver robust mechanical properties, with a minimum tensile strength of 480 MPa and at least 15% elongation. Their impressive machinability and precise 0.02 mm tolerance make them an excellent choice for applications where strength, durability, and accurate dimensions are paramount.

Versatility Across Industrial Sectors

These brass rods are utilized in various industries such as marine, electrical, engineering, and automotive due to their superior corrosion resistance and electrical conductivity (28% IACS). Their reliability and compliance with IS 319 and BS 2874 CZ112 standards ensure safety and performance across all manufacturing needs.

Customizable Options and Quality Assurance

Offered in multiple tempers, shapes, and sizes, our rods are customizable to project specifications. Each product is carefully finished and packaged in wooden cases or customized bundles to guarantee arrival in pristine condition, ready for immediate use in manufacturing processes.

FAQs of 2.055 High Tensile Brass Rods:

Q: How are 2.055 High Tensile Brass Rods typically used in various industries?

A: These rods are widely applied in engineering, automotive, marine, and electrical sectors for making gears, fasteners, precision automotive parts, electrical terminals, decorative elements, and industrial components owing to their strength, machinability, and corrosion resistance.Q: What makes 2.055 High Tensile Brass Rods beneficial for component manufacturing?

A: Their excellent machinability, combined with high tensile strength and precise dimensional tolerance, reduces tool wear, provides reliable performance, and enables efficient high-volume production of intricate components.Q: Where can 2.055 High Tensile Brass Rods be sourced for bulk requirements?

A: These rods are available through various distributors, exporters, manufacturers, suppliers, service providers, and traders in India, often supported by international export and customizable packaging solutions.Q: What manufacturing standards do these brass rods comply with?

A: 2.055 High Tensile Brass Rods are manufactured to meet IS 319 and BS 2874 CZ112 standards, ensuring consistent quality and compatibility with global industrial requirements.Q: When should a specific temper (hard, half hard, quarter hard) be selected?

A: The choice of temper depends on the desired characteristicshard temper is preferred for maximum strength, half hard offers a balance of ductility and strength, while quarter hard provides more flexibility for parts needing moderate strength and easier forming.Q: How does the surface finish of the rods enhance their application?

A: Polished or smooth finishes not only improve the appearance with a golden yellow color but also enhance corrosion resistance, making the rods suitable for visible or decorative components in marine and architectural applications.Q: What is the typical packing process for 2.055 High Tensile Brass Rods during shipment?

A: To ensure safe transit and storage, the rods are packed in wooden cases, bundles, or customized packaging as per client requirements, protecting them from physical damage and environmental exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com