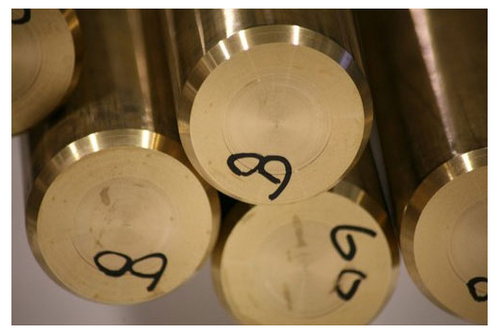

C67400 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade C67400

- Tolerance 0.05 mm

- Alloy C67400

- Temper Hard

- Length Standard/Customized (up to 6 meters)

- Click to View more

C67400 High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

C67400 High Tensile Brass Rods Product Specifications

- 0.05 mm

- Standard/Customized (up to 6 meters)

- 6 mm to 63 mm

- Hard

- Varies as per dimension (approximately 0.3 kg/m for 8 mm dia)

- C67400

- Golden Yellow

- C67400

- Brass

- High Tensile Brass Rod

- Round

C67400 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

C67400 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Mechanical Performance

C67400 High Tensile Brass Rods are specially formulated for high-stress environments, offering a tensile strength of up to 600 MPa and hardness in a range suitable for demanding engineering and marine applications. The alloys notable ductility is reflected in its minimum 15% elongation, making it reliable under both tension and impact.

Versatile Applications Across Industries

Thanks to their excellent corrosion resistance and machinability, these rods are highly sought after for automotive parts, electrical connectors, valve components, and marine fittings. Industries choose C67400 rods for their adaptability and cost-effectiveness in manufacturing and assembly processes.

Customizable Dimensions and Finishes

Available in standard and tailored diameters from 6 mm to 63 mm and up to 6 meters in length, C67400 rods can be supplied in bright, polished, or mill finishes. Their precise dimensions with a tight tolerance of 0.05 mm ensure they meet the most stringent project requirements.

FAQs of C67400 High Tensile Brass Rods:

Q: How are C67400 High Tensile Brass Rods manufactured?

A: C67400 rods are typically produced through hot extrusion, followed by drawing and heat treatment processes according to ASTM B124/B150 standards, ensuring optimal properties such as high strength and good machinability.Q: What industries commonly use C67400 High Tensile Brass Rods?

A: These brass rods are widely used in the automotive, electrical, engineering, valve manufacturing, and marine fittings industries, owing to their excellent mechanical and corrosion-resistant properties.Q: When should I choose C67400 brass rods over other brass types?

A: C67400 is preferred when high tensile strength, good elongation, and superior corrosion resistance are required, particularly in applications exposed to harsh environments or mechanical stress.Q: Where can I source C67400 High Tensile Brass Rods in India?

A: C67400 rods are available through major distributors, exporters, manufacturers, service providers, suppliers, and traders across India, many of whom offer both standard and custom lengths and diameters.Q: What is the process for customizing rod length and diameter?

A: Custom sizes are achieved by precision cutting and machining the rods to the clients specifications, within a tight tolerance of 0.05 mm, ensuring suitable fit and performance for specific applications.Q: How do C67400 rods benefit valve manufacturing and marine fittings?

A: Their excellent corrosion resistance and high strength make them ideal for environments exposed to moisture and variable pressure, ensuring long-lasting reliability and reduced maintenance in valves and marine components.Q: What finish options are offered for these brass rods?

A: The rods are available in bright, polished, and mill finishes, allowing customers to select the most suitable appearance and surface characteristic for their applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com