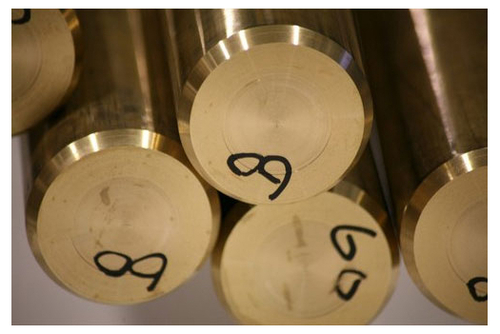

CC765S High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CC765S (CuZn36Pb3) / CW713R

- Tolerance 0.05 mm

- Alloy CC765S

- Temper As per requirement

- Length Up to 5000 mm (custom sizes available)

- Click to View more

CC765S High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CC765S High Tensile Brass Rods Product Specifications

- Varies as per dimension

- Yellowish Golden

- As per requirement

- CC765S

- CC765S (CuZn36Pb3) / CW713R

- High Tensile Brass Rod

- Round, Hexagonal, Square, Rectangular

- Up to 5000 mm (custom sizes available)

- 5 mm to 200 mm

- Brass

- 0.05 mm

CC765S High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CC765S High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Exceptional Mechanical Properties

CC765S brass rods offer impressive tensile strength of up to 650 MPa, ensuring reliability in high-stress environments. The hardness ranges between 90-120 HB, making these rods suitable for applications demanding durability and wear resistance, such as bushings, fasteners, and valve parts.

Precision and Versatility in Dimensions

These rods are fabricated in various formsround, hexagonal, square, and rectangularwith diameters from 5 mm to 200 mm and lengths up to 5000 mm, including customized sizes. Their tight tolerance of 0.05 mm ensures consistent performance and compatibility with precision engineering requirements.

Superior Surface Finish and Corrosion Resistance

With a smooth, bright yellowish golden finish, CC765S brass rods not only enhance the aesthetic of finished products but also provide excellent resistance to corrosion. This makes them especially ideal for marine environments and any setting where long-term durability and appearance matter.

FAQs of CC765S High Tensile Brass Rods:

Q: How are CC765S high tensile brass rods typically used in engineering and marine applications?

A: These rods are employed for manufacturing heavy-duty fasteners, bushes, valve parts, and critical structural components where high strength and corrosion resistance are necessary, especially in demanding environments like marine and industrial sectors.Q: What process is used to manufacture and finish CC765S brass rods?

A: CC765S brass rods are produced through stringent extrusion and drawing processes, followed by surface treatments to achieve a smooth, bright finish. This ensures precision in dimensions and enhances machinability.Q: When should I choose CC765S grade over other types of brass rods?

A: Opt for the CC765S grade when applications require higher tensile strength (up to 650 MPa), excellent corrosion resistance, and reliable machinability, particularly for critical engineering or marine components.Q: Where are CC765S brass rods supplied from, and who are the typical suppliers?

A: These rods are widely supplied throughout India by manufacturers, exporters, distributors, traders, and service providers specializing in high-performance brass products, with packaging available in secure wooden boxes or bundled forms.Q: What benefits does the high conductivity of CC765S brass rods provide?

A: With a conductivity rating of 12-15% IACS, these rods efficiently conduct electricity and heat, making them suitable for applications requiring both mechanical strength and moderate electrical performance.Q: How can customers request custom sizes for CC765S brass rods?

A: Clients can specify their required diameters (between 5 mm and 200 mm) and lengths (up to 5000 mm) to obtain brass rods tailored to their projects exact dimensions, ensuring optimal fit and function.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com