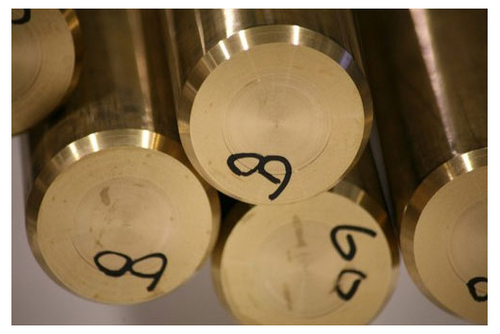

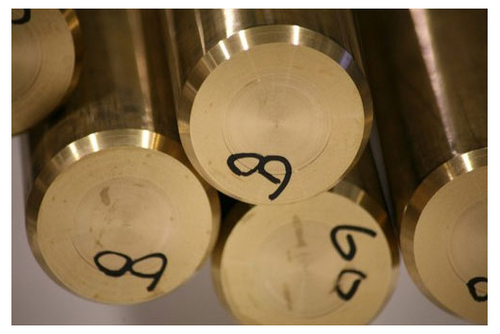

IS 304 HTB 2 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade IS 304 HTB 2

- Tolerance Close tolerance, h9/h11 or as per IS-304

- Alloy IS 304 HTB 2

- Temper HTB 2

- Length Custom / Standard Lengths available (typically up to 6 meters)

- Click to View more

IS 304 HTB 2 High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

IS 304 HTB 2 High Tensile Brass Rods Product Specifications

- HTB 2

- 5 mm to 120 mm (custom sizes available)

- Varies with dimensions; typically specified per meter

- IS 304 HTB 2

- Brass

- Round / Hexagonal / Square

- Close tolerance, h9/h11 or as per IS-304

- Yellowish Golden

- IS 304 HTB 2

- High Tensile Brass Rod

- Custom / Standard Lengths available (typically up to 6 meters)

IS 304 HTB 2 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

IS 304 HTB 2 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Outstanding Mechanical Strength

IS 304 HTB 2 High Tensile Brass Rods deliver superior strength and durability with a tensile strength ranging from 500 to 800 MPa and a minimum yield strength of 400 MPa. Their elongation of at least 12% ensures resilience, making them ideal for components requiring both flexibility and toughness across various industries.

Versatility for Demanding Applications

Engineered for performance, these rods are suitable for marine, electrical, hardware, valve manufacturing, and other precision applications. The exceptional machinability, compatible with CNC and traditional methods, allows seamless fabrication of intricate parts while maintaining performance integrity.

Reliable Quality and Compliance

Manufactured under IS 304 HTB 2 and ASTM B16/B124 standards, these brass rods guarantee consistent quality. Available in multiple shapes, diameters (5120 mm), and lengths (up to 6 meters), they come in both standard and custom packing, ensuring safe delivery and compliance with project specifications.

FAQs of IS 304 HTB 2 High Tensile Brass Rods:

Q: How can IS 304 HTB 2 High Tensile Brass Rods be used in marine environments?

A: IS 304 HTB 2 High Tensile Brass Rods are highly resistant to corrosion, making them ideal for marine applications such as hardware, fasteners, and precision components exposed to harsh sea conditions. Their non-magnetic nature and durability further enhance performance in marine settings.Q: What process is recommended for machining these brass rods?

A: These rods are suitable for high-speed CNC machining as well as conventional turning and milling processes. Their high machinability allows for precise shaping without compromising structural integrity, facilitating efficient production of complex components.Q: When should I choose a low lead, environment-friendly variant?

A: Select the low lead variant when environmental compliance or specific regulations require minimal lead content, particularly in applications involving potable water, food processing, or environmentally sensitive areas. This ensures adherence to safety and eco-friendly standards.Q: Where are IS 304 HTB 2 High Tensile Brass Rods primarily supplied from?

A: They are predominantly distributed, exported, and manufactured in India, with suppliers offering standard and custom packing for safe, global delivery based on client requirements.Q: What are the main benefits of using these brass rods?

A: Key benefits include high tensile and yield strength, excellent corrosion resistance, close dimensional tolerance, superior machinability, and the availability of various shapes and sizes tailored to specific industry needs.Q: How are the rods usually packed for export or delivery?

A: IS 304 HTB 2 High Tensile Brass Rods are supplied in standard export packing to ensure safety during transit, with custom packing options available upon request to accommodate unique handling or project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com