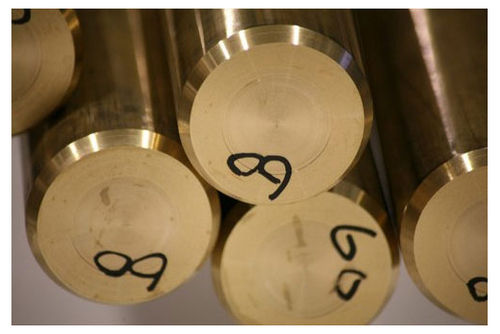

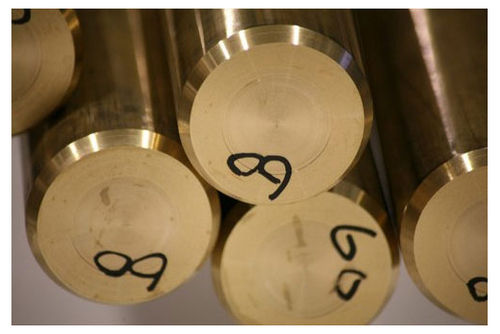

CuZn39AlFeMn High Tensile Brass Rods

Product Details:

- Type Rod

- Material Brass

- Grade High Tensile

- Tolerance 0.05 mm

- Alloy CuZn39AlFeMn

- Temper Hard

- Length 1 to 6 meters

- Click to View more

CuZn39AlFeMn High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CuZn39AlFeMn High Tensile Brass Rods Product Specifications

- Round

- 10mm to 100mm

- Variable as per size

- Golden

- 1 to 6 meters

- Rod

- Brass

- 0.05 mm

- CuZn39AlFeMn

- Hard

- High Tensile

CuZn39AlFeMn High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CuZn39AlFeMn High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Exceptional Strength for Demanding Applications

The CuZn39AlFeMn High Tensile Brass Rods provide outstanding mechanical properties, including a minimum tensile strength of 600 MPa and a yield strength of over 300 MPa. Their high strength, excellent elongation, and good hardness ratings make them a reliable choice for industries requiring robust, long-lasting components such as hydraulic parts and marine hardware.

Precision Engineering and Surface Quality

These rods are crafted with strict tolerances (0.05 mm) to ensure precise dimensions. The smooth and bright finish not only enhances aesthetics but also improves performance in applications where surface quality matters, like valve bodies and heavy-duty bearings. Available in various diameters and lengths, customization options are accessible to suit specific project requirements.

Reliability in Harsh Environments

CuZn39AlFeMn High Tensile Brass Rods are non-magnetic and highly resistant to corrosion, making them perfect for marine and industrial use. Their robust composition resists degradation, ensuring longevity even in demanding environments. Their versatility and trusted performance have earned them a reputation as a preferred solution for engineers and manufacturers in India and abroad.

FAQs of CuZn39AlFeMn High Tensile Brass Rods:

Q: How are CuZn39AlFeMn High Tensile Brass Rods typically used in industry?

A: These rods are commonly used in manufacturing valve bodies, marine hardware, heavy-duty bearings, and hydraulic components due to their high strength, excellent machinability, and corrosion resistance.Q: What benefits does the CuZn39AlFeMn alloy offer over standard brass rods?

A: The CuZn39AlFeMn alloy provides higher tensile and yield strength, superior hardness, and enhanced durability, making it suitable for applications requiring exceptional mechanical performance and resistance to wear and corrosion.Q: What is the manufacturing process for these brass rods?

A: The rods are produced through a combination of hot extrusion and cold drawing processes, guaranteeing precise dimensions, a smooth surface finish, and adherence to strict international standards including IS 3209, EN 12164, and BS 2874 CZ 114.Q: Where can these brass rods be supplied?

A: As a leading distributor, exporter, manufacturer, supplier, service provider, and trader based in India, we supply CuZn39AlFeMn High Tensile Brass Rods to domestic and international markets, with customizable packaging options such as wooden crates or as per client requirement.Q: When should you choose CuZn39AlFeMn High Tensile Brass Rods for your application?

A: Select these rods when you require components that must withstand high mechanical stress, resist corrosion, and maintain dimensional accuracy over timeespecially in marine, hydraulic, and heavy-duty industrial settings.Q: How does the non-magnetic property benefit industrial applications?

A: The non-magnetic nature of these rods makes them ideal for applications where magnetic interference must be minimized, such as in electronic assemblies and marine environments.Q: What is the tolerance and dimensional range available for these rods?

A: CuZn39AlFeMn High Tensile Brass Rods are supplied in diameters from 10mm to 100mm, lengths of 1 to 6 meters, and feature a tight tolerance of 0.05 mm, ensuring consistent quality and fit for precision engineering needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com