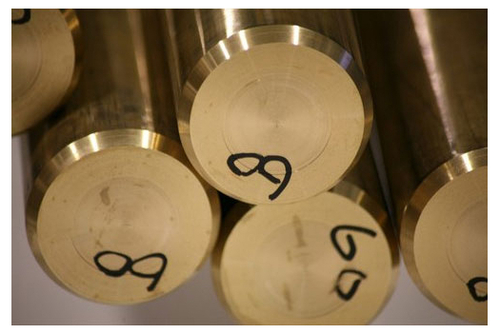

CuZn35Mn2AlFe1-C High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CuZn35Mn2AlFe1-C

- Tolerance 0.05 mm

- Alloy CuZn35Mn2AlFe1-C

- Temper Hard

- Length 3 meters

- Click to View more

CuZn35Mn2AlFe1-C High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CuZn35Mn2AlFe1-C High Tensile Brass Rods Product Specifications

- 0.05 mm

- CuZn35Mn2AlFe1-C

- High Tensile Brass Rod

- CuZn35Mn2AlFe1-C

- 10 mm to 100 mm

- Brass

- As per size

- 3 meters

- Hard

- Round

- Golden Yellow

CuZn35Mn2AlFe1-C High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CuZn35Mn2AlFe1-C High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Exceptional Corrosion Resistance

The CuZn35Mn2AlFe1-C brass rods are notably resistant to corrosion, making them an optimal choice for marine hardware and environments with high moisture or chemical exposure. Their specialized alloy composition maintains structural integrity and longevity, even under challenging conditions.

Versatile Applications

Thanks to their high tensile strength, reliable machinability, and excellent surface finish, these rods serve a diverse range of industries. Automotive component manufacturers, marine equipment suppliers, and engineering firms value these rods for both their performance and adaptability across multiple uses.

Precision and Standards Compliance

Manufactured to stringent tolerances of 0.05 mm and adhering to EN 12164, IS 320, and ASTM B16 standards, each rod ensures consistent quality. The rods are supplied in a polished, golden yellow hue that combines aesthetic appeal with exceptional technical performance.

FAQs of CuZn35Mn2AlFe1-C High Tensile Brass Rods:

Q: How are CuZn35Mn2AlFe1-C High Tensile Brass Rods typically used?

A: These rods are widely utilized in automotive components, marine hardware, and general engineering due to their high strength, superior corrosion resistance, and attractive surface finish.Q: What are the main benefits of using CuZn35Mn2AlFe1-C brass rods?

A: The primary advantages include excellent tensile strength (550800 MPa), good machinability, exceptional corrosion resistance, and a polished, bright appearance. Their versatility makes them suitable for diverse industrial sectors.Q: When should these high tensile brass rods be used over conventional brass alloys?

A: They are ideal when applications demand higher mechanical strength, durability, and maximum corrosion resistance, such as in marine or automotive environments.Q: Where are these rods commonly distributed and supplied from?

A: These rods are readily available across India from reputable distributors, exporters, manufacturers, suppliers, traders, and service providers specializing in non-ferrous metals.Q: What is the typical manufacturing process for CuZn35Mn2AlFe1-C rods?

A: The rods are produced through a precise extrusion or rolling process, followed by heat treatment such as annealing, then surface finishing to achieve a bright, polished appearance.Q: How does the machinability of these brass rods affect their suitability for engineering applications?

A: With a good machinability rating, these rods are easy to machine into complex components, reducing production time and maintaining tight tolerances, which is highly valued in engineering and fabrication.Q: What specifications ensure the consistency of these brass rods during large-scale projects?

A: Adherence to international standards (EN 12164 / IS 320 / ASTM B16), a tolerance of 0.05 mm, and availability in a range of diameters (10100 mm) and lengths (3 meters) assure uniformity and compatibility for volume requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com