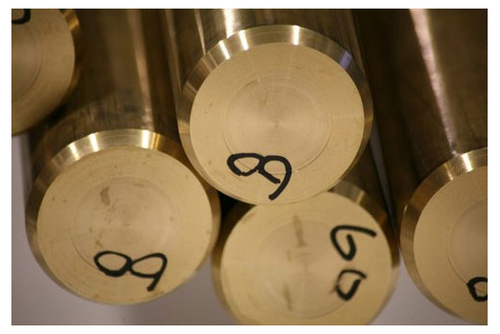

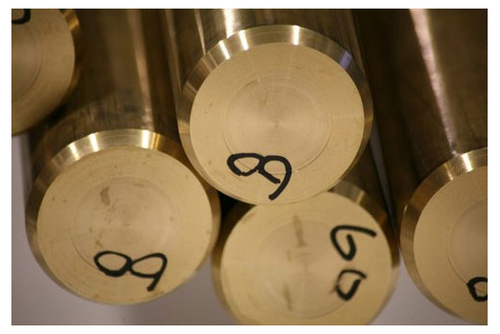

CW722 R High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CW722R

- Tolerance h9, h11 or as specified

- Alloy CW722R (CZ112)

- Temper As Rolled / Hard / Half Hard

- Length 1m, 2m, 3m or custom

- Click to View more

CW722 R High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CW722 R High Tensile Brass Rods Product Specifications

- CW722R (CZ112)

- High Tensile Brass Rod

- 1m, 2m, 3m or custom

- Golden Yellow

- Brass

- CW722R

- As Rolled / Hard / Half Hard

- Variable as per size

- 8mm to 100mm

- Round, Hex, Square

- h9, h11 or as specified

CW722 R High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CW722 R High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Exceptional Mechanical and Corrosion Properties

CW722 R Brass Rods are engineered for applications demanding high mechanical strength and reliability. They maintain excellent performance in marine and industrial environments due to superb corrosion resistance. Their robust construction and precision tolerances make them suitable for harsh operating conditions while ensuring component longevity.

Tailored for Manufacturing Versatility

These rods offer machinability at 80% compared to free-cutting brass, supporting efficient production of complex components. With availability in numerous shapesround, hex, and squareand flexible size and temper options, manufacturers can order products meeting exact specifications for a wide array of industrial uses.

FAQs of CW722 R High Tensile Brass Rods:

Q: How are CW722 R High Tensile Brass Rods typically used in industry?

A: CW722 R rods are utilized in the manufacturing of marine fittings, valve stems, high-strength fasteners, gears, and other heavy-duty components due to their excellent mechanical and corrosion-resistant properties.Q: What process ensures the corrosion resistance of these brass rods?

A: The inherent composition of the CW722 R alloy, combined with precise manufacturing per EN standards, provides outstanding corrosion resistance, especially suitable for marine and industrial environments where durability is essential.Q: When should I choose CW722 R rods over standard brass rods?

A: CW722 R rods are preferable when applications demand higher tensile strength, better machinability (80%), and reliable performance in corrosive environments, such as in marine or industrial settings.Q: Where can CW722 R High Tensile Brass Rods be sourced in India?

A: These rods are available through a range of distributors, exporters, manufacturers, service providers, suppliers, and traders throughout India, ensuring accessible procurement for diverse industry sectors.Q: What are the benefits of the available finishes and surface qualities?

A: Finishes like bright, mill, or custom provide not only aesthetic value but also help meet specific functional or production requirements. A smooth, clean surface ensures optimal performance and easy further processing.Q: How are the rods customized to meet specific project requirements?

A: CW722 R High Tensile Brass Rods are available in various diameters (8mm to 100mm), lengths (1m, 2m, 3m, or custom), shapes (round, hex, square), temper conditions, and tolerances (h9, h11, or as specified), enabling tailored solutions for unique application needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com