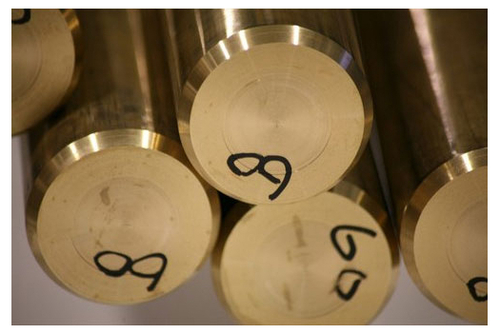

CW721 R High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CW721R

- Tolerance H9 / H11

- Alloy CW721R (CZ114)

- Temper As per requirement

- Length Customizable (Standard up to 3 meters)

- Click to View more

CW721 R High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CW721 R High Tensile Brass Rods Product Specifications

- CW721R (CZ114)

- H9 / H11

- Brass

- As per requirement

- Golden Yellow

- CW721R

- High Tensile Brass Rod

- Customizable (Standard up to 3 meters)

- 10 mm to 100 mm

- Depends on length and diameter

- Round / Hex / Square

CW721 R High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CW721 R High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Engineered for High Performance

CW721R High Tensile Brass Rods deliver the perfect blend of strength and ductility, making them suitable for critical industrial sectors. The rods conform to strict EN 12164 and EN 12165 standards, ensuring reliable mechanical properties and dimensional tolerances required in high-stress environments. Their corrosion resistance also enhances product lifespan.

Versatile Applications

With their excellent machinability and customizable lengths and diameters, CW721R rods are used to create precision automotive parts, marine components, fastening systems, and various engineering products. Their high tensile strength and bright golden finish also make them a preferred choice for both functional and decorative uses.

Comprehensive Sourcing in India

As a leading distributor, exporter, manufacturer, service provider, supplier, and trader in India, we offer CW721R brass rods tailored to diverse requirements. Whether you need large bulk orders or specific dimensions, our expert support ensures you receive the exact product specifications needed for your project.

FAQs of CW721 R High Tensile Brass Rods:

Q: How are CW721R High Tensile Brass Rods manufactured to achieve such mechanical strength?

A: CW721R High Tensile Brass Rods are produced using high-quality brass alloy CZ114 and are processed under strict conditions to meet EN 12164/12165 standards. Advanced forging and extrusion techniques ensure their tensile strength of 550-750 MPa and uniform hardness, making them suitable for engineering applications.Q: What are the primary benefits of using CW721R rods in automotive and marine applications?

A: These rods provide excellent corrosion resistance, high tensile strength, and robust machinability, making them ideal for automotive and marine parts that require durability and precision. Their resistance to wear and environmental factors extends service life in harsh operating conditions.Q: When should I choose CW721R brass rods over standard brass rods?

A: CW721R brass rods should be selected when your application demands higher tensile strength, superior elongation, and reliable machinability. They are particularly advantageous for engineering components where both mechanical and corrosion resistance properties are critical.Q: Where can I source CW721R rods with customized dimensions in India?

A: CW721R rods with tailored lengths (up to 3 meters) and diameters (10 mm to 100 mm) can be sourced through authorized distributors, exporters, manufacturers, and suppliers across India. Customized shapes including round, hex, or square sections are also available to meet specific project needs.Q: What is the standard process for machining CW721R brass rods?

A: CW721R rods are known for good machinability, rated at 80%. Standard machining processes such as turning, milling, and drilling can be used, with the rods providing smooth chip formation and reduced tool wear for efficient production cycles.Q: How do I determine the appropriate rod diameter and length for my project?

A: Select diameter and length based on engineering requirements such as mechanical load, application design, and available space. Our technical support can assist with material selection and customization to ensure optimal performance in your specific use case.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com