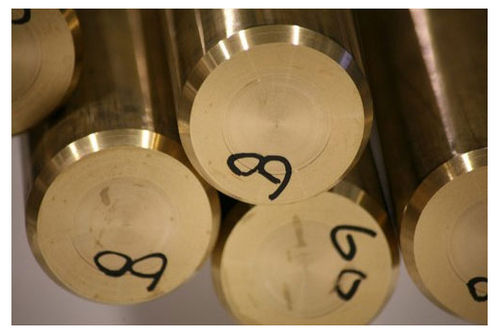

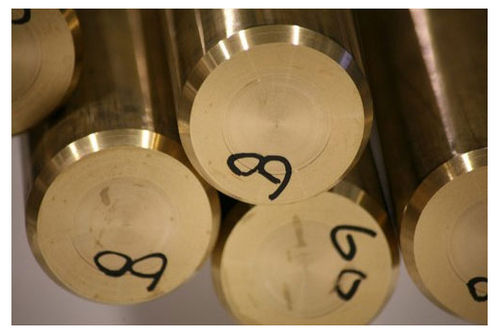

IS 320 HT2 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rods

- Material Brass

- Grade HT2

- Tolerance +/- 0.02 mm

- Alloy IS 320 HT2

- Temper Hard

- Length 200 mm to 5000 mm

- Click to View more

IS 320 HT2 High Tensile Brass Rods Price And Quantity

- 250 Kilograms

- 350.00 - 450.00 INR/Kilograms

IS 320 HT2 High Tensile Brass Rods Product Specifications

- 200 mm to 5000 mm

- Golden Yellow

- +/- 0.02 mm

- High Tensile Brass Rods

- Round

- 5 mm to 100 mm

- Hard

- HT2

- IS 320 HT2

- Custom depending on size

- Brass

IS 320 HT2 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

IS 320 HT2 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Engineered for High Performance

The IS 320 HT2 High Tensile Brass Rods deliver superior mechanical properties, offering an ideal combination of strength, durability, and workability. Their excellent machinability and high conductivity make them a preferred choice for electrical and engineering applications that demand reliability and precision.

Diverse Applications Across Industries

These brass rods are utilized in a range of sectors including automobiles, electrical components, general engineering, and fastener manufacturing. Their inherent corrosion resistance and robust nature suit both interior and exterior uses, making them versatile for any industrial requirement.

Quality Packaging and Sizing Options

We offer IS 320 HT2 High Tensile Brass Rods in various diameters and lengths, ensuring tailored solutions for every project. Our packagingbundles or sturdy wooden boxesprovides optimal protection during transit and storage, ensuring the rods reach you in pristine condition.

FAQs of IS 320 HT2 High Tensile Brass Rods:

Q: How are IS 320 HT2 High Tensile Brass Rods manufactured to meet stringent quality standards?

A: These rods are produced using high-quality brass alloy conforming to IS 320:1981 standards and undergo meticulous inspection. Precision engineering ensures the correct temper (hard), diameter, and length, with strict tolerance control (0.02 mm) for consistent performance.Q: What are the main applications of IS 320 HT2 High Tensile Brass Rods?

A: IS 320 HT2 brass rods are commonly used in the manufacture of automobile parts, engineering components, electrical fittings, and fasteners due to their high tensile strength, excellent machinability, and corrosion resistance.Q: When is it beneficial to choose high tensile brass rods over standard grades?

A: High tensile brass rods are ideal when the application requires stronger mechanical properties, higher durability, and improved resistance to wear, such as in heavy-duty engineering, automotive, or electrical environments.Q: Where are these brass rods typically supplied from and to?

A: These rods are manufactured, distributed, and exported globally by suppliers, traders, and manufacturers across India, delivering to domestic and international markets based on specific client requirements.Q: What is the standard process for installing or machining IS 320 HT2 High Tensile Brass Rods?

A: Thanks to their excellent machinability, these rods can be cut, drilled, or turned using conventional machining equipment, allowing for easy integration into components or assemblies during manufacturing.Q: What are the key benefits of using IS 320 HT2 High Tensile Brass Rods in industrial applications?

A: The rods provide a robust balance of strength, elongation, and conductivity, along with a bright finish and outstanding corrosion resistanceoffering long-term reliability and efficiency in various industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com