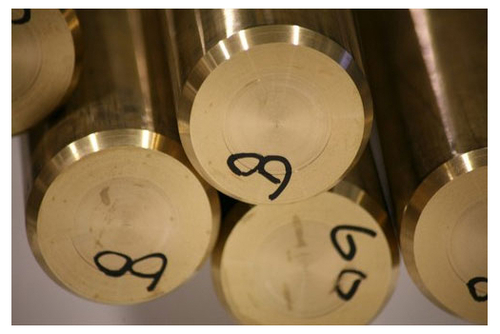

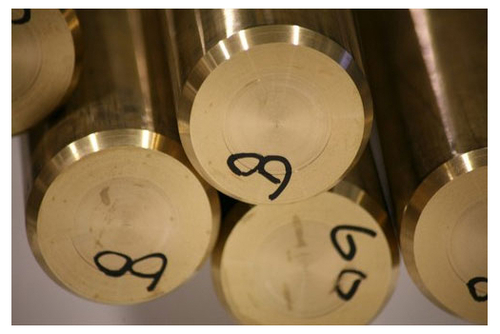

2.034 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rods

- Material Brass

- Grade CW718R / CZ114

- Tolerance +/- 0.05 mm

- Alloy 2.034 (CuZn40Pb2) / ASTM B16

- Temper Hard (H), Half Hard (HH), Quarter Hard (QH)

- Length 3 to 6 meters (custom lengths available)

- Click to View more

2.034 High Tensile Brass Rods Price And Quantity

- 250 Kilograms

- 350.00 - 450.00 INR/Kilograms

2.034 High Tensile Brass Rods Product Specifications

- As per dimension and length

- Brass

- 3 to 6 meters (custom lengths available)

- Bright Golden Yellow

- CW718R / CZ114

- High Tensile Brass Rods

- 4 mm to 100 mm

- +/- 0.05 mm

- Round, Hexagonal, Square

- Hard (H), Half Hard (HH), Quarter Hard (QH)

- 2.034 (CuZn40Pb2) / ASTM B16

2.034 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

2.034 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Strength for Demanding Applications

With a tensile strength of at least 500 MPa and elongation of 12% minimum, 2.034 High Tensile Brass Rods provide exceptional mechanical integrity. Designed to meet rigorous requirements, these rods are ideal for environments where reliability and strength are crucial, making them suitable for automotive components, engineering solutions, and fastener production.

Precise Manufacturing and Flexible Dimensions

Available in round, hexagonal, and square profiles, these brass rods offer dimensional versatility with diameters from 4 mm to 100 mm and custom lengths between 3 to 6 meters. Manufactured with a tolerance of +/- 0.05 mm, they guarantee consistency and reliability for intricate machining and assembly processes.

Excellent Corrosion Resistance and Surface Finish

The rods feature outstanding resistance to corrosion, making them perfect for marine, electrical, and plumbing applications. Their smooth and bright surface ensures minimal oxidation and provides an attractive, golden yellow finish that enhances product aesthetics while maintaining functionality.

FAQs of 2.034 High Tensile Brass Rods:

Q: How are 2.034 High Tensile Brass Rods typically used in industry?

A: These rods are widely utilized in automotive, engineering, fastener, marine, electrical, and plumbing industries due to their strength, corrosion resistance, and machinability. Common uses include components, connectors, bushings, valves, and hardware.Q: What is the process for manufacturing these High Tensile Brass Rods?

A: The rods are produced through precision extrusion or drawing under strict EN 12164 or EN 12167 standards, followed by hardening to desired tempers (H, HH, QH). Quality control checks ensure they meet mechanical, dimensional, and surface finish criteria before packaging.Q: When should I choose rods with different tempers, such as Hard, Half Hard, or Quarter Hard?

A: Selection of temper depends on your applications requirements. Choose Hard (H) for maximum strength, Half Hard (HH) for balanced toughness and ductility, and Quarter Hard (QH) when some flexibility and ease of forming are necessary.Q: Where can I source these brass rods in India?

A: These products are distributed, exported, manufactured, and traded by various suppliers across India, offering customized packaging and prompt delivery according to your needs.Q: What benefit does the high machinability offer to users?

A: High machinability enables efficient and precise shaping, reducing tool wear and extending machine life. This results in improved production rates, cost-efficiency, and excellent finished part quality.Q: How is the corrosion resistance of these rods advantageous?

A: Excellent corrosion resistance protects the rods from environmental degradation, especially in marine and plumbing applications, ensuring lasting performance and minimal maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com