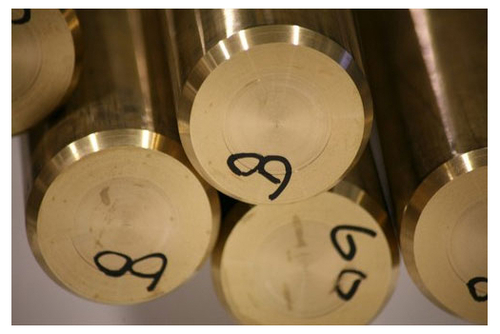

CuZn35Al5 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CuZn35Al5

- Tolerance h9 or as specified

- Alloy CuZn35Al5

- Temper As per requirement

- Length Up to 5 meters

- Click to View more

CuZn35Al5 High Tensile Brass Rods Price And Quantity

- 250 Kilograms

- 350.00 - 450.00 INR/Kilograms

CuZn35Al5 High Tensile Brass Rods Product Specifications

- Brass

- h9 or as specified

- As per requirement

- Up to 5 meters

- CuZn35Al5

- Round, Hex, Square

- CuZn35Al5

- 4 mm to 80 mm

- Variable as per size

- Golden Yellow

- High Tensile Brass Rod

CuZn35Al5 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CuZn35Al5 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Performance for Demanding Applications

CuZn35Al5 High Tensile Brass Rods deliver robust mechanical properties, making them ideal for high-stress environments in engineering, marine, and electrical sectors. Their outstanding tensile strength, hardness, and corrosion resistance ensure reliability and longevity, even in challenging conditions. Flexible sizes and tempers allow for customization to meet customer requirements, enhancing versatility in application.

Precision Standards and Tailored Configurations

Manufactured as per IS 320, BS 2874, and DIN 17660 standards, these brass rods meet stringent industry benchmarks. With h9 tolerance and temper options as requested, customers receive high precision and consistent quality. The rods are available in various shapes, including round, hex, and square, with lengths up to 5 meters, ensuring seamless integration into a range of manufacturing and assembly processes.

FAQs of CuZn35Al5 High Tensile Brass Rods:

Q: How are CuZn35Al5 high tensile brass rods manufactured and finished?

A: These rods are produced using advanced extrusion or drawing methods under strict adherence to IS 320, BS 2874, and DIN 17660. They undergo precision processing to achieve bright drawn or specified surface finishes, with tolerances such as h9, ensuring uniform dimensions and superior appearance.Q: What industries commonly use CuZn35Al5 high tensile brass rods?

A: These brass rods are widely utilized in engineering, marine, electrical, fasteners, and general industrial applications due to their combination of high strength, good machinability, and excellent corrosion resistance in harsh environments.Q: When should you choose CuZn35Al5 over standard brass rods?

A: CuZn35Al5 rods are recommended when high tensile strength (500850 MPa), increased hardness (up to 180 HB), and superior corrosion resistance are critical, especially in marine or industrial atmospheres where standard brass may not suffice.Q: Where can CuZn35Al5 brass rods be sourced or supplied in India?

A: They are available from distributors, exporters, manufacturers, service providers, suppliers, and traders specializing in brass alloys throughout India. Custom orders regarding length, diameter, and temper can be accommodated by established suppliers.Q: What benefits do CuZn35Al5 high tensile brass rods offer for marine and electrical components?

A: Their excellent resistance to seawater and industrial chemicals, coupled with reliable electrical conductivity and machinability, make them a preferred choice for marine hardware, connectors, terminals, and related components exposed to demanding conditions.Q: How does the machinability of CuZn35Al5 compare to other brass alloys?

A: CuZn35Al5 offers good machinability, allowing for efficient turning, drilling, and threading, which reduces production time and tool wear, enhancing productivity in machining operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com