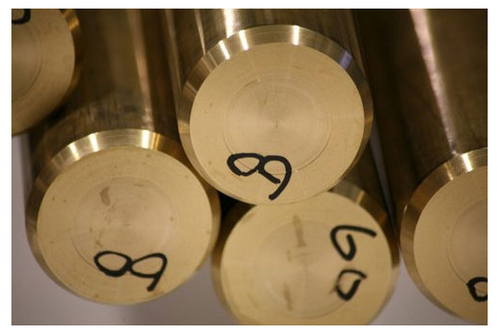

BS1400 HTB1 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rods

- Material Brass

- Grade HTB1

- Tolerance +/- 0.1 mm

- Alloy BS1400 HTB1

- Temper As Rolled / Drawn

- Length Customized, Standard Lengths available

- Click to View more

BS1400 HTB1 High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

BS1400 HTB1 High Tensile Brass Rods Product Specifications

- HTB1

- Golden Yellow

- 4 mm to 80 mm

- Round

- As Rolled / Drawn

- Customized, Standard Lengths available

- +/- 0.1 mm

- BS1400 HTB1

- Dependent on size and length, supplied as per order

- Brass

- High Tensile Brass Rods

BS1400 HTB1 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

BS1400 HTB1 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Strength and Durability

The BS1400 HTB1 high tensile brass rods achieve exceptional strength with a tensile range of 490 - 700 MPa, making them an ideal choice for demanding mechanical components. Their robust construction supports prolonged use in critical applications such as fasteners and fittings that require durability and a reliable performance over time.

Outstanding Corrosion Resistance

Designed to withstand atmospheric conditions, these rods provide excellent corrosion resistance, ensuring longevity in a variety of environments. Their robust brass alloy composition makes them suitable for both indoor and outdoor uses, helping to reduce maintenance and replacement costs for manufacturers and end-users.

Flexible Manufacturing Options

The rods are available in customized lengths and standard diameters from 4 mm to 80 mm, supporting a wide spectrum of industrial requirements. Combined with accurate tolerance of +/- 0.1 mm, they fit seamlessly into precise engineering applications, making them a versatile option for diverse manufacturing needs.

FAQs of BS1400 HTB1 High Tensile Brass Rods:

Q: What are the main applications of BS1400 HTB1 high tensile brass rods?

A: BS1400 HTB1 high tensile brass rods are commonly used in machining parts, valves, fittings, and fasteners due to their strength, machinability, and resistance to corrosion.Q: How does the corrosion resistance of HTB1 brass rods benefit various industries?

A: With excellent corrosion resistance in atmospheric conditions, these rods are ideal for use in environments where durability is essential, reducing the need for frequent maintenance or replacement.Q: Where are BS1400 HTB1 brass rods typically supplied from and to which locations?

A: As a distributor, exporter, manufacturer, supplier, trader, and service provider based in India, BS1400 HTB1 rods are supplied domestically within India and exported to various international markets.Q: What is the manufacturing process for these high tensile brass rods?

A: BS1400 HTB1 brass rods are produced using as-rolled or drawn processes, which enhance their tensile strength and achieve the desired mechanical properties and surface finish.Q: When should you choose HTB1 grade brass rods over other alloys?

A: HTB1 grade brass rods should be chosen when a combination of high tensile strength, low lead content, good machinability, and superior corrosion resistance is required for the application.Q: How are the rods packaged for transportation and delivery?

A: To ensure safety during transportation, the rods are bundled and packed in robust wooden boxes, preventing damage and preserving quality during shipping.Q: What is the range of available diameters and can custom sizes be ordered?

A: The standard diameter range is from 4 mm to 80 mm. Custom lengths and sizes can be supplied based on order specifications to meet unique project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com