CUAL11NI5FE5 Aluminum Bronze

Product Details:

- Technique Hot Rolled

- Temper Hard

- Product Type Metal Plate

- Material Aluminum Bronze

- Alloy CUAL11NI5FE5

- Shape Plate

- Dimension (L*W*H) As per customer requirement

- Click to View more

CUAL11NI5FE5 Aluminum Bronze Price And Quantity

- 480 INR/Gram

- 250 , , Kilograms

- 450.00 - 500.00 INR/Gram

CUAL11NI5FE5 Aluminum Bronze Product Specifications

- CUAL11NI5FE5

- Metal Plate

- Industrial and Engineering applications

- Golden

- Hot Rolled

- Plate

- As per customer requirement

- Custom/As ordered

- Hard

- Aluminum Bronze

CUAL11NI5FE5 Aluminum Bronze Trade Information

- 20000 , , Kilograms Per Month

- 4 Week

Product Description

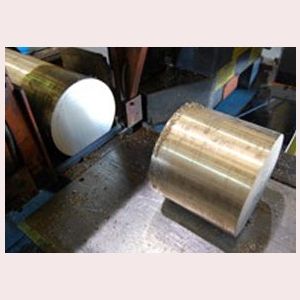

CUAL11NI5FE5 Aluminum Bronze

The aluminum bronze CuAl11Ni5Fe5 is used in aeronautical industry, due to its high mechanical properties and oxidation resistance. The alloy CuAl11Ni5Fe5 is resistant to corrosion in saline mist area.

Typical Uses for CUAL11NI5FE5 Aluminum Bronze :-

Aerospace: Landing Gear Bushings & Bearings, Guides, Nuts

Heavy Industry: Civil engineering, iron and steel industry, manufacturing guides, rolling mills

Equivalent Specifications:

| Specifications | Designation |

| Europen | CuAl11Fe6Ni6 |

| Germany | CuAl11Ni6Fe5 |

Chemical Composition:

|

| Al | Cr | Co | Cu | Fe | Pb | Mn | Ni | Sn | Zn |

| Min/Max | 10.0 - 11.0 | 0.05 | 0.2 | 74.5 min | 4.0 - 5.5 | 0.03 | 1.5 | 4.2 - 6.0 | 0.25 | 0.3 |

| Nominals | 10.5 | - | - | - | 4.7 | - | - | 5.1 | - | - |

Physical Properties:

| Product Property | Value |

| Density | 7.58 g/cm³ |

| Melting Point | 1035 °C |

| Modulus of Elasticity | 115 GPa |

| Thermal Conductivity | 37.7 W/m.K |

Mechanical Property:

| Mechanical Property | Value |

| Proof Stress | 400-530 MPa |

| Tensile Strength | 600-760 MPa |

| Elongation A50 mm | 15-5 % |

| Hardness Vickers | 170 to 220 HV |

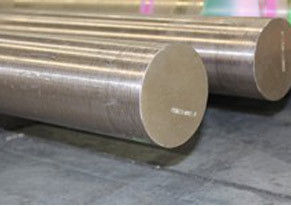

Sizes Available:

| ROUND RODS | 8mm To 70 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

High Strength and Durability

CUAL11NI5FE5 Aluminum Bronze is valued for its robust mechanical propertieshigh tensile and yield strength, as well as good hardness. These qualities ensure its reliability and longevity in heavy-duty industrial settings while retaining enough ductility for essential fabrications.

Exceptional Corrosion Resistance

This alloy delivers outstanding protection against saltwater and marine atmospheres, making it indispensable in marine, offshore, and chemical environments. Its resistance significantly extends component lifecycle, reducing maintenance and replacement needs.

Versatile Customization and Supply

Available in custom plate dimensions and weights, CUAL11NI5FE5 can be produced as per specific project demands. Whether for small custom orders or large-scale production, our flexible supply chain accommodates all requirements, serving distributors, exporters, and manufacturers across India.

FAQs of CUAL11NI5FE5 Aluminum Bronze:

Q: How is CUAL11NI5FE5 Aluminum Bronze typically used in industrial applications?

A: CUAL11NI5FE5 Aluminum Bronze is commonly employed in demanding engineering applications requiring high strength, corrosion resistance, and durability, such as marine hardware, pump components, valve parts, and structural plates exposed to harsh environments.Q: What benefits does this alloy offer in marine and saltwater environments?

A: This material provides exceptional corrosion resistance against saltwater and marine atmospheres, ensuring longevity and minimal maintenance for maritime structures or equipment. Its chemical stability makes it preferable for offshore and coastal installations.Q: When should CUAL11NI5FE5 Aluminum Bronze be chosen over other bronzes?

A: Select CUAL11NI5FE5 when applications require a blend of superior mechanical strength, good machinability, and excellent resistance to aggressive environments, especially where exposure to saline or harsh chemicals is expected.Q: Where can CUAL11NI5FE5 plates be sourced and what customization options are available?

A: CUAL11NI5FE5 plates can be sourced from authorized distributors, exporters, and manufacturers across India. Customization is available for plate size, surface finish, hardness, and order quantities, ensuring each projects specific needs are met.Q: What is the typical process for manufacturing this Aluminum Bronze alloy?

A: The alloy is produced through a hot rolling technique, allowing precise control of plate thickness and surface finish as per customer specifications. The process ensures a hard temper and consistent properties throughout the material.Q: How does the machinability of CUAL11NI5FE5 impact its use?

A: Its good machinability enables efficient fabrication into complex parts and fine components without excessive tool wear, facilitating cost-effective production and adaptability for various engineering designs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminium Bronze' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com