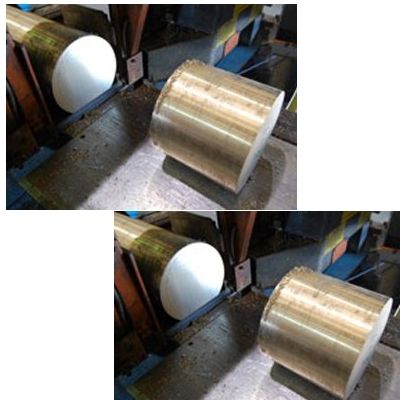

C95400 Aluminum Bronze

Product Details:

- Technique Casting

- Temper As Cast

- Product Type Bar, Plate, Custom Components

- Material Aluminum Bronze

- Alloy C95400

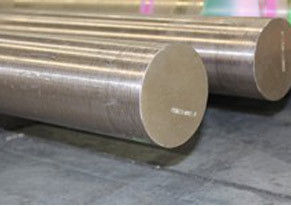

- Shape Round Bar, Plate

- Dimension (L*W*H) Customizable

- Click to View more

C95400 Aluminum Bronze Price And Quantity

- 250 , , Kilograms

- 480 INR/Kilograms

- 450.00 - 500.00 INR/Kilograms

C95400 Aluminum Bronze Product Specifications

- Bushings, Bearings, Gears, Wear Plates

- Round Bar, Plate

- Casting

- C95400

- Aluminum Bronze

- Bar, Plate, Custom Components

- Golden Bronze

- As per requirement

- Customizable

- As Cast

C95400 Aluminum Bronze Trade Information

- 20000 , , Kilograms Per Month

- 4 Week

Product Description

C95400 ALUMINUM BRONZE

The aluminum bronze C95400 is also called C954. It is the most popular and all purpose high yield aluminum bronze alloy with high tensile strength, ductility, welding ability and resistance to wear, fatigue and deformation under shock or overload. The alloy is used while manufacturing bearings, gears, valve components, wear-plate and wear-strip in conformation with continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

Typical Uses for C954 Aluminum Bronze:

Automotive : Weld Guns

Fasteners : Nuts, Large Hold Down Screws

Industrial : Pickling Hooks, Bearings, Pawl, Worm Gears, Machine Parts, Spur Gears, Heavily Loaded Worm Gears, Pump Parts, Landing Gear Parts, Valve Bodies, Valve Guides, Valve Seats, Bearing Segments for the Steel Industry, Pressure Blocks for the Steel Industry, High Strength Clamps, Bushings, Valves, Gears

Marine:Ship Building, Covers for Marine Hardware

Ordinance:Government Fittings

Equivalent Specifications:

| Specifications | Designation |

| Italy | CuAl11Fe4 |

Chemical Composition:

|

| Al | Cu | Fe | Mn | Ni |

| Min/Max | 10.0-11.5 | 83.0 min | 3.0-5.0 | 0.5 | 1.5 |

| Nominals | 10.8000 | 83.2000 | 4.0000 | - | - |

Specifications:

| End Product | Specification |

| Centrifugal | ASME SB271, ASTM B271, SAE J462, J461 |

| Continuous | ASTM B505, SAE J462, J461 |

| Ingot | ASTM B30 |

| Permanent | ASTM B806 |

| Precision | MILITARY MIL-C-11866 |

| Sand | ASME SB148, ASTM B66, B148, B763, SAE J461, J462 |

Fabrication:

| Joining Technique | Suitability |

| Brazing | Good |

| Coated Metal Arc Welding | Good |

| Gas Shielded Arc Welding | Good |

| Machinability Rating | 60 |

| Oxyacetylene Welding | Not Recommended |

| Soldering | Good |

Physical Properties:

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 9.0 10-6 per oF (68-572 F) | 16.2 10-6 per oC (20-300 C) |

| Density | 0.269 lb/in3 at 68 F | 7.45 gm/cm3 @ 20 C |

| Electrical Conductivity | 13 %IACS @ 68 F | 0.75 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 80.2 ohms-cmil/ft @ 68 F | 13.33 microhm-cm @ 20 C |

| Magnetic Permeability (As Cast) | 1.27 | 1.27 |

| Magnetic Permeability (TQ50 temper) | 1.2 | 1.2 |

| Melting Point Liquidus | 1900 F | 1038 C |

| Melting Point Solidus | 1880 F | 1027 C |

| Modulas of Elasticity in Tension | 15500 ksi | 107000 MPa |

| Specific Gravity | 7.45 | 7.45 |

| Specific Heat Capacity | 0.1 Btu/lb/oF at 68 F | 419.0 J/kg oK at 293 K |

| Thermal Conductivity | 33.9 Btu ft/(hr ft2oF)at 68F | 58.7 W/m oK at 20 C |

Sizes Available

| ROUND RODS | 8mm To 70 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

Versatile Alloy for Demanding Applications

C95400 Aluminum Bronze stands out as a reliable option for components operating under high load and adverse conditions. Its excellent resistance to wear and seawater corrosion makes it indispensable for bushings, bearings, and gears in marine, industrial, and heavy machinery sectors. Customization in dimensions ensures a precise fit for various engineering requirements.

Precision Casting for Superior Quality

Manufactured using advanced casting techniques, this alloy guarantees uniformity and strength across bars and plates. The as-cast temper retains optimal mechanical properties, making it suitable for further processing or direct use. Stringent control over composition and casting processes ensures the consistent delivery of premium products.

FAQs of C95400 Aluminum Bronze:

Q: How is C95400 Aluminum Bronze commonly used in industrial settings?

A: C95400 Aluminum Bronze is frequently used for components that demand strength, durability, and resistance to corrosion, such as bushings, bearings, gears, and wear plates. Its capability to withstand intensive loads and harsh environments makes it a preferred choice in marine, mining, and heavy machinery industries.Q: What process is used to manufacture C95400 Aluminum Bronze products?

A: C95400 Aluminum Bronze products are produced through casting techniques, following the ASTM B148 standard. The alloy is melted, poured into molds, and then cooled to create round bars, plates, or custom shapes with consistent mechanical and physical properties.Q: When should engineers consider using C95400 Aluminum Bronze over other materials?

A: Engineers should choose C95400 Aluminum Bronze when exceptional corrosion resistance, particularly in seawater or chemical settings, and high mechanical strength are essential. Its good machinability, wear resistance, and service temperature capacity up to 260C provide further advantage in demanding applications.Q: Where can C95400 Aluminum Bronze be sourced in India?

A: Manufacturers, suppliers, exporters, and distributors throughout India offer C95400 Aluminum Bronze in various forms and dimensions. Many service providers accommodate custom requirements, making it accessible for a broad spectrum of industrial projects.Q: What are the main benefits of selecting C95400 Aluminum Bronze for engineering applications?

A: The principal advantages include high tensile and yield strength, excellent resistance to marine and industrial corrosives, good machinability, and adaptability for custom dimensions. Its longevity reduces maintenance needs in heavy-duty and high-wear environments.Q: How does the composition of C95400 Aluminum Bronze impact its properties?

A: The combination of 1011.5% aluminum, 35% iron, and the balance copper enhances strength, hardness, and corrosion resistance. This specific alloy configuration gives it a golden bronze appearance, robust mechanical properties, and makes it suitable for both functional and decorative tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminium Bronze' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com