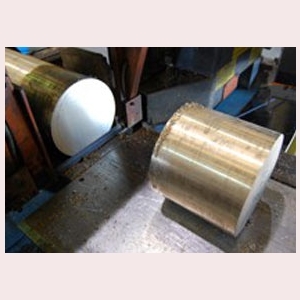

C62500 ALUMINUM BRONZE

Product Details:

- Technique Hot Rolled

- Temper Hard

- Product Type Non-Ferrous Metal Bars

- Material Aluminum Bronze

- Alloy C62500

- Shape Round Bar

- Dimension (L*W*H) Different Available

- Click to View more

C62500 ALUMINUM BRONZE Price And Quantity

- 250 , , Kilograms

- 450.00 - 500.00 INR/Kilograms

- 480 INR/Kilograms

C62500 ALUMINUM BRONZE Product Specifications

- C62500

- Hard

- Non-Ferrous Metal Bars

- Industrial

- Round Bar

- Hot Rolled

- Aluminum Bronze

- Different Available

- Golden Yellow

- Customized

C62500 ALUMINUM BRONZE Trade Information

- 20000 , , Kilograms Per Month

- 4 Week

Product Description

C62500 ALUMINUM BRONZE

Typical Uses

Industrial: Guide Bushings, Wear Strips, Cams, Dies, Forming Rolls, Sheet Metal Forming Dies, Wing Dies for Vertical Tube Benders, Bushings, Wear Plates for Plastic Molds, Welding Rod, Plastic Mold Components

Sizes Available :

| ROUND RODS | 8mm To 70 mm |

| HEX | 10mm To 60mm |

| SQUARE | 10mm To 60mm |

| FLAT | 10mm Min Thickness and max Width 120mm |

| BILLETS | Up to 200 mm |

| INGOTS | As per Specification |

CHEMICAL COMPOSITION

|

| Cu | Al | Fe | Mn |

| Min./Max. | Rem. | 12.5-13.5 | 3.5-5.5 | 2.0 |

| Nominal | 82.7 | 13.0 | 4.3 | - |

SPECIFICATIONS

| End Product | Specification |

| Rod, Welding | AWS A5.13 |

FABRICATION

| Joining Technique | Suitability |

| Soldering | Not Recommended |

| Brazing | Fair |

| Oxyacetylene Welding | Not Recommended |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Good |

| Spot Weld | Fair |

| Seam Weld | Fair |

| Butt Weld | Fair |

| Capacity for Being Cold Worked | Not Recommended |

| Capacity for Being Hot Formed | Excellent |

| Forgeability Rating | 80 |

| Machinability Rating | 20 |

PHYSICAL PROPERTIES

| Product Property | US Customary | Metric |

| Melting Point - Liquidus | 1925 F | 1052 C |

| Melting Point - Solidus | 1917 F | 1047 C |

| Density | 0.260 lb/in3 at 68 F | 7.2 gm/cm3 @ 20 C |

| Specific Gravity | 7.210 | 7.21 |

| Electrical Resistivity | 104 ohms-cmil/ft @ 68 F | 17.29 microhm-cm @ 20 C |

| Electrical Conductivity | 10 %IACS @ 68 F | 0.059 MegaSiemens/cm @ 20 C |

| Thermal Conductivity | 27 Btu ft/(hr ft2oF)at 68F | 46.7 W/m oK at 20 C |

| Coefficient of Thermal Expansion | 9 ·10-6 per oF (68-572 F) | 16.2 10-6 per oC (20-300 C) |

| Specific Heat Capacity | 0.090 Btu/lb/oF at 68 F | 377.1 J/kg oK at 293 K |

| Modulas of Elasticity in Tension | 16000 ksi | 110000 MPa |

Exceptional Strength and Corrosion Resistance

With a unique combination of aluminum, iron, and nickel, C62500 Aluminum Bronze exhibits high tensile and yield strengths paired with outstanding corrosion resistance. These features make it an ideal choice for demanding industrial operations, especially where resistance to wear and atmospheric corrosion is vital.

Versatility and Customization

Available in various shapes, such as round bars, rods, and bushes, C62500 Aluminum Bronze can be tailored to specific industrial requirements. Its hard temper and smooth, bright finish enhance both functional performance and aesthetic appeal. Custom dimensions and weights further support diverse application needs.

FAQs of C62500 ALUMINUM BRONZE:

Q: How is C62500 Aluminum Bronze typically used in industrial environments?

A: C62500 Aluminum Bronze is primarily used for components subject to high stress and wear, such as bushings, bearings, and rods. Its excellent corrosion resistance and strength make it suitable for marine, chemical processing, and heavy machinery industries.Q: What are the benefits of choosing C62500 Aluminum Bronze over other alloys?

A: Key benefits include superior corrosion resistance, high mechanical strength, and good formability. Its bright, smooth finish and golden yellow color also add an aesthetic advantage when appearance is important.Q: When should I specify ASTM B124/B150 standards for Aluminum Bronze components?

A: ASTM B124/B150 should be specified when high reliability and performance are required, ensuring consistent chemical composition and mechanical properties of C62500 Aluminum Bronze for critical industrial applications.Q: Where can C62500 Aluminum Bronze be sourced in India?

A: C62500 Aluminum Bronze is available through leading distributors, exporters, manufacturers, service providers, suppliers, and traders across India, offering customized solutions to meet specific industry needs.Q: What is the typical manufacturing process for C62500 Aluminum Bronze round bars?

A: C62500 Aluminum Bronze round bars are produced using hot rolling techniques, followed by finishing processes to achieve the required hardness, dimensional accuracy, and smooth, bright surfaces.Q: How does the machinability of C62500 Aluminum Bronze compare with other copper alloys?

A: C62500 offers fair machinability, which is slightly more challenging than some standard copper alloys but manageable with proper tooling and practices, thanks to its alloy composition.Q: What precautions should be taken during the processing or usage of C62500 Aluminum Bronze?

A: Due to its hard temper and specific alloying elements, appropriate machining tools and cutting fluids should be used. Adequate ventilation is also important during processing to avoid exposure to fumes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminium Bronze' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com