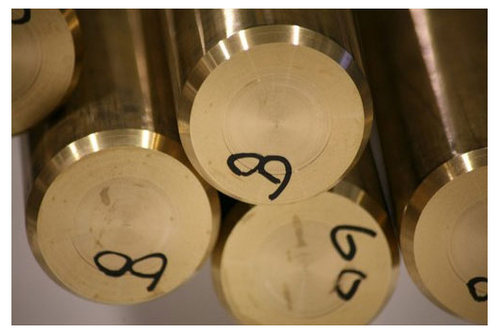

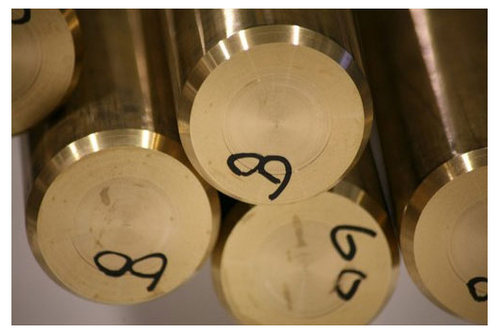

CuZn25Al5Mn4Fe3-C High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CuZn25Al5Mn4Fe3-C

- Tolerance 0.5 mm

- Alloy CuZn25Al5Mn4Fe3-C

- Temper Hard, Half Hard, Annealed

- Length 2-6 meters, customizable

- Click to View more

CuZn25Al5Mn4Fe3-C High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CuZn25Al5Mn4Fe3-C High Tensile Brass Rods Product Specifications

- 10 mm to 100 mm

- CuZn25Al5Mn4Fe3-C

- 0.5 mm

- Varies as per size and length

- 2-6 meters, customizable

- Brass

- Round, Hex, Square

- Hard, Half Hard, Annealed

- Golden Yellow

- High Tensile Brass Rod

- CuZn25Al5Mn4Fe3-C

CuZn25Al5Mn4Fe3-C High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CuZn25Al5Mn4Fe3-C High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Outstanding Performance for Multiple Industries

CuZn25Al5Mn4Fe3-C brass rods are tailored for sectors requiring reliable, high-strength, and corrosion-resistant components. Their versatility makes them an ideal choice for gears, marine hardware, engineering parts, and aerospace assemblies. The rods are compatible with various industrial processes owing to their superior machinability and adaptable specifications.

Precision Manufacturing and Quality Assurance

Produced in accordance with international standards like EN 12164 and ASTM B124, these rods undergo strict quality checks ensuring consistency and precision. The tight tolerance of 0.5 mm and customizable dimensions cater to specific engineering requirements, enhancing structural integrity and operational safety.

Flexible Supply and Export Packaging

As a distributor, exporter, manufacturer, and service provider in India, we deliver CuZn25Al5Mn4Fe3-C rods in export-worthy bundles and wooden boxes, safeguarding them during transit. Our packaging solutions uphold the quality of the product for worldwide shipping, meeting the needs of global buyers.

FAQs of CuZn25Al5Mn4Fe3-C High Tensile Brass Rods:

Q: How are the CuZn25Al5Mn4Fe3-C High Tensile Brass Rods manufactured to ensure high strength?

A: The rods are produced using advanced alloying techniques with copper, zinc, aluminum, manganese, and iron, followed by processes such as extrusion and controlled tempering (hard, half hard, annealed) to achieve superior tensile strength and durability.Q: What industries typically use CuZn25Al5Mn4Fe3-C brass rods?

A: These brass rods are widely used in engineering, marine, aerospace, hardware, and gear manufacturing due to their excellent strength, corrosion resistance, and machinability.Q: When should I choose high tensile brass rods over standard brass rods?

A: High tensile brass rods are recommended when your application demands enhanced mechanical strength, greater durability, and improved resistance to corrosion, especially in demanding environments like marine and aerospace settings.Q: Where can the CuZn25Al5Mn4Fe3-C brass rods be sourced or supplied?

A: We supply these rods throughout India and globally as a distributor, exporter, manufacturer, and service provider, with shipments securely packaged for domestic and international delivery.Q: What is the process for customizing the size and length of these rods?

A: Customers can specify required lengths (from 2 to 6 meters) and diameters (10 mm to 100 mm) during ordering, and we manufacture the rods according to these custom dimensions while maintaining tight tolerance control.Q: How does the excellent machinability benefit users?

A: The rods offer excellent machinability, enabling efficient precision machining, reducing production time, and allowing for the fabrication of intricate components without compromising strength or quality.Q: What surface finish is typically provided on these brass rods and why is it advantageous?

A: The standard surface finish is bright and clean, which enhances the visual appeal, reduces the risk of contamination, and supports better performance in engineering and decorative applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com