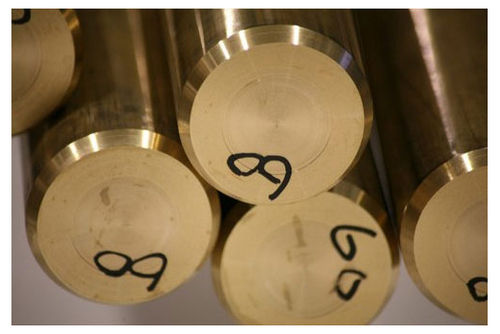

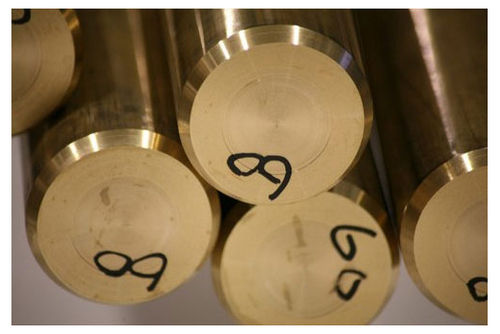

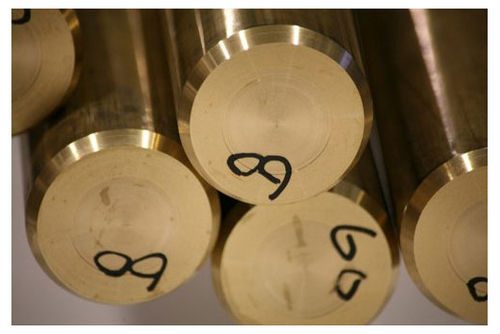

CZ135 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade CZ135

- Tolerance 0.05 mm

- Alloy CZ135

- Temper Hot Rolled / Annealed

- Length 3 to 6 Meter

- Click to View more

CZ135 High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CZ135 High Tensile Brass Rods Product Specifications

- CZ135

- 10 mm to 100 mm

- CZ135

- 3 to 6 Meter

- 0.05 mm

- Brass

- Golden Yellow

- Hot Rolled / Annealed

- High Tensile Brass Rod

- Round, Hex, Square, Flat

- Variable as per size

CZ135 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CZ135 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Mechanical Properties

CZ135 Brass Rods deliver high tensile strength (55,00070,000 PSI) and exceptional elongation (at least 15%), making them well-suited for applications that demand durability and resilience. Their consistent tolerance of 0.05 mm ensures precise fitting in a range of industrial applications, contributing significantly to structural reliability and safety.

Versatile Applications Across Industries

Engineered for versatility, CZ135 rods are commonly used in engineering, automotive, electrical, and marine environments. The rods good machinability and excellent corrosion resistance make them a preferred choice for fabricating intricate components and structural parts where both strength and conductivity are paramount.

Customizable Sizes and Finishes

With availability in shapes such as round, hex, square, and flat, along with polished or bright finishes, the CZ135 rods can be tailored to specific technical requirements. Lengths vary from 3 to 6 meters, and diameters from 10 to 100 mm. This customization enables seamless integration into diverse design and manufacturing processes.

FAQs of CZ135 High Tensile Brass Rods:

Q: How are CZ135 High Tensile Brass Rods typically used in industry?

A: CZ135 High Tensile Brass Rods are employed in a wide range of sectors, including engineering, automotive, electrical, and marine industries. Their superior mechanical properties and corrosion resistance make them ideal for manufacturing fasteners, connectors, gears, and marine fittings where strength, machinability, and durability are essential.Q: What standards and grades do CZ135 brass rods conform to?

A: These rods comply with BS 2874 CZ135 and IS 319 / 4413 standards, ensuring consistent quality and performance. The grade is CZ135, recognized for its high tensile properties and suitability for demanding industrial applications.Q: When should I choose CZ135 brass rods over other brass alloys?

A: Select CZ135 rods when your project requires high tensile strength (55,00070,000 PSI), excellent elongation (minimum 15%), and top-notch corrosion resistance. Their balanced machinability and strength make them preferable for components subjected to constant stress or harsh environments.Q: Where can I source CZ135 High Tensile Brass Rods in India?

A: As a major distributor, exporter, manufacturer, supplier, trader, and service provider based in India, CZ135 brass rods are available through established suppliers who ensure quality assurance and reliable packaging in bundles or wooden boxes for safe delivery.Q: What is the manufacturing process of CZ135 brass rods?

A: CZ135 rods are produced using hot rolling or annealing techniques to achieve the desired mechanical properties. Rigorous quality control is applied to maintain precise tolerances (0.05 mm) and polished or bright finishes, meeting both technical and aesthetic requirements.Q: How does CZ135 brass rods composition benefit its performance?

A: With a lead content of no more than 0.3%, CZ135 rods offer improved machinability while maintaining strength. Their density of 8.50 g/cm and excellent corrosion resistance ensure long-term performance in challenging conditions, particularly critical for marine and electrical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com