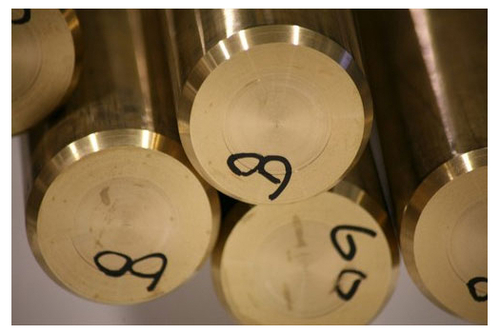

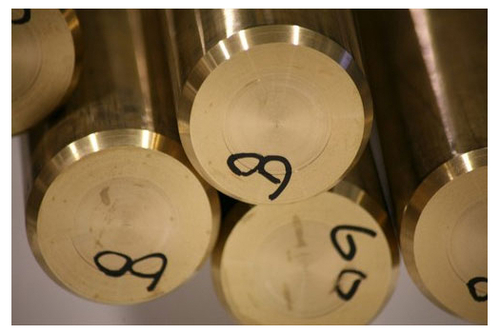

CZ114 High Tensile Brass Rods

Product Details:

- Type Rod

- Material High Tensile Brass

- Grade CZ114

- Tolerance 0.05 mm

- Alloy CZ114

- Temper Hard

- Length 1 meter to 6 meters

- Click to View more

CZ114 High Tensile Brass Rods Price And Quantity

- 250 Kilograms

- 350.00 - 450.00 INR/Kilograms

CZ114 High Tensile Brass Rods Product Specifications

- Hard

- CZ114

- 0.05 mm

- High Tensile Brass

- CZ114

- Round

- Varies by diameter and length

- 10 mm to 100 mm

- Golden Yellow

- 1 meter to 6 meters

- Rod

CZ114 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CZ114 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Mechanical Strength

CZ114 high tensile brass rods are engineered for durability, offering a tensile strength of 540-740 MPa and a yield strength of at least 200 MPa. With a minimum elongation of 12%, they are reliable for applications requiring resilience and resistance to deformation under stress.

Polished, Bright Finish

These rods receive a specialized surface treatment resulting in a polished and bright appearance, ensuring not only aesthetic appeal but also added surface protection. The smooth finish also assists in precise dimensional tolerance, vital for engineering applications.

Diverse Engineering Applications

Designed to meet the stringent demands of automotive, electrical, marine, and engineering sectors, CZ114 rods are versatile and adaptable. Their high machinability and uniform alloy composition facilitate production efficiency and consistent product quality.

FAQs of CZ114 High Tensile Brass Rods:

Q: How are CZ114 high tensile brass rods typically used in engineering applications?

A: CZ114 brass rods are commonly selected for components requiring high strength, such as gears, valve stems, fasteners, connectors, and marine hardware. Their excellent machinability and structural integrity make them a preferred choice for precision engineering and heavy-duty automated systems.Q: What benefits does the polished surface finish provide on CZ114 rods?

A: The bright, polished surface of CZ114 rods enhances visual appeal and imparts additional resistance to tarnish and surface oxidation. This finish also aids in achieving finer tolerances during secondary processing, making them suitable for visible or decorative applications.Q: Where can CZ114 high tensile brass rods be sourced in India?

A: CZ114 rods are available through leading distributors, suppliers, manufacturers, and exporters across India. They can be purchased directly from service providers and traders that specialize in non-ferrous metal rod supplies, catering to both bulk and customized demands.Q: What is the manufacturing process for CZ114 high tensile brass rods?

A: CZ114 brass rods are produced by melting and alloying copper with zinc and a controlled amount of lead, followed by casting, hot rolling, drawing, and precise polishing. Each rod is manufactured to meet BS2874/EN12164 standards, ensuring dimensional accuracy and performance.Q: When should you consider using CZ114 brass rods over other brass grades?

A: CZ114 rods are ideal when your application demands higher tensile strength and good machinability without compromising on corrosion resistance. This makes them suitable for heavy-duty mechanical parts and marine components where performance and durability are paramount.Q: What are the size and packing options for CZ114 brass rods?

A: Rod diameters range from 10 mm to 100 mm and lengths from 1 meter to 6 meters. Depending on customer requirements and order quantities, they are supplied either in bundled form or packed inside durable wooden cases for secure transport and storage.Q: How does the lead content in CZ114 rods influence their applications?

A: With a maximum lead content of 0.25%, CZ114 brass rods maintain high machinability while minimizing environmental and health risks. This controlled composition ensures suitability for precision parts that require intricate machining.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com