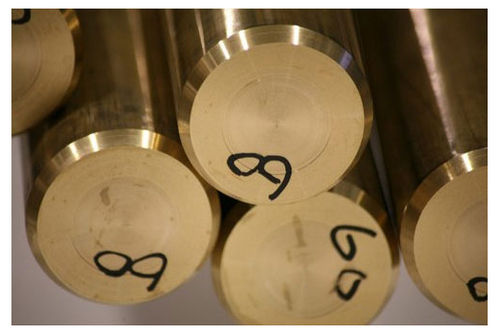

BS1400 HTB3 High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade BS1400 HTB3

- Tolerance 0.2 mm

- Alloy HTB3

- Temper As per BS1400 specification

- Length Up to 6 meters (custom lengths available)

- Click to View more

BS1400 HTB3 High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

BS1400 HTB3 High Tensile Brass Rods Product Specifications

- Brass

- Up to 6 meters (custom lengths available)

- High Tensile Brass Rod

- Round Rod

- Golden Yellow

- 0.2 mm

- BS1400 HTB3

- HTB3

- Variable as per dimensions

- 8 mm to 50 mm (custom sizes available)

- As per BS1400 specification

BS1400 HTB3 High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

BS1400 HTB3 High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Superior Mechanical Properties

BS1400 HTB3 brass rods exhibit outstanding mechanical characteristics, including high tensile and yield strength, coupled with a minimum elongation of 15%. Their Brinell hardness ranges from 140 to 180 HB, making them suitable for harsh working environments and high-stress applications.

Exceptional Corrosion Resistance

The HTB3 alloys excellent corrosion resistance ensures long-term durability, especially in marine and hydraulic settings. This makes these rods reliable for outdoor and moisture-prone installations, retaining both strength and appearance over time.

Versatile Engineering Applications

These rods are widely used for producing valves, marine hardware, air brake components, and hydraulic systems. Their good machinability allows for easy fabrication into custom shapes and sizes, supporting diverse engineering requirements.

FAQs of BS1400 HTB3 High Tensile Brass Rods:

Q: How are BS1400 HTB3 High Tensile Brass Rods manufactured and finished?

A: These rods are produced using refined brass alloy HTB3 as per BS1400 specifications. Advanced processes ensure a bright, smooth surface, tight tolerances (0.2 mm), and uniform mechanical properties. Custom lengths and diameters are available upon request.Q: What makes BS1400 HTB3 High Tensile Brass Rods suitable for marine and hydraulic applications?

A: The rods offer excellent corrosion resistance, high tensile strength, and reliable hardness, ensuring longevity and performance in environments exposed to moisture, chemicals, and high pressure, such as marine fittings and hydraulic systems.Q: When should I specify BS1400 HTB3 rods for an engineering project?

A: These rods are ideal when your application demands strong, corrosion-resistant material with good machinabilitycommon in valves, air brakes, marine fittings, and other high-stress engineering uses.Q: Where can custom dimensions for BS1400 HTB3 Brass Rods be requested?

A: Custom lengths up to 6 meters and diameters from 8 mm to 50 mm are available directly from leading distributors, manufacturers, and suppliers throughout India. Contact your vendor for specific requirements.Q: What is the advantage of using BS1400 HTB3 alloy rods over other brass grades?

A: BS1400 HTB3 rods provide a balance of high tensile strength, superior machining capability, and enhanced corrosion resistance, making them more versatile and durable than standard brass grades for heavy-duty projects.Q: How do BS1400 HTB3 Brass Rods benefit machining and fabrication processes?

A: Thanks to their good machinability and consistent surface quality, these rods allow for precise shaping and minimal tool wear during fabrication, reducing overall production cost and lead times.Q: What finishing and appearance can I expect from BS1400 HTB3 rods?

A: Each rod features a bright, smooth finish with a distinctive golden yellow color, enhancing both aesthetic value and functional reliability for visible installations or components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com