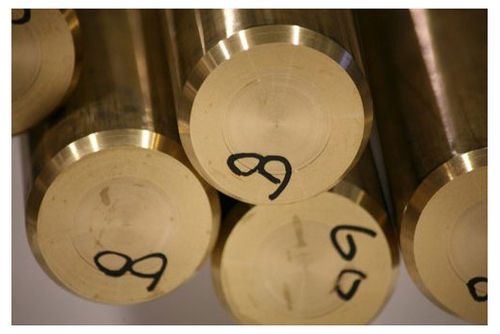

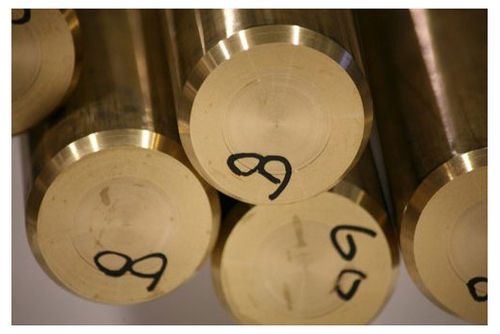

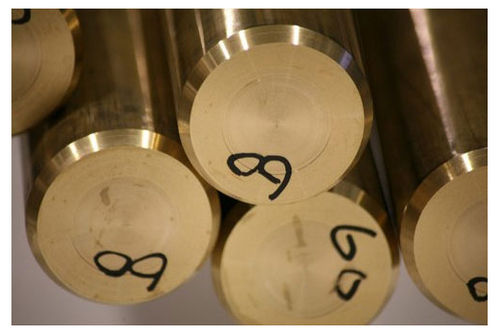

CuZn36Al4FeMn High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rods

- Material Brass

- Grade CuZn36Al4FeMn

- Tolerance +/-0.02 mm

- Alloy CuZn36Al4FeMn

- Temper As per requirement

- Length 1 to 6 meters

- Click to View more

CuZn36Al4FeMn High Tensile Brass Rods Price And Quantity

- 350.00 - 450.00 INR/Kilograms

- 250 Kilograms

CuZn36Al4FeMn High Tensile Brass Rods Product Specifications

- 1 to 6 meters

- +/-0.02 mm

- Brass

- As per requirement

- CuZn36Al4FeMn

- CuZn36Al4FeMn

- Round / Hex / Square

- Golden Yellow

- 10mm - 100mm

- Varies with size

- High Tensile Brass Rods

CuZn36Al4FeMn High Tensile Brass Rods Trade Information

- 20000 Kilograms Per Month

- 4 Week

Product Description

CuZn36Al4FeMn High Tensile Brass Rods

CW713R is a high tensile brass which is alloyed with aluminum, manganese and silicon etc. which makes this alloy almost as hard as aluminum bronze, but considerably easier to process. CW713R also has good corrosion, wear resistance and machinability.

Typically this alloy is used in the automotive and hydraulic industries in forms of products such as Bearings for high load, slide-& wear-plates, valve guides, piston parts etc.

Chemical Composition

|

| Cu | Pb | Sn | Zn | Si | Ni | Fe | Al | Mn | Other |

| Min | 57 | 0.2 | - | - | 0.3 | - | - | 1.3 | 1.5 | - |

| Max | 59 | 0.8 | Max 0.4 | Rem | 1.3 | Max 1.0 | Max 1.0 | 2.3 | 3.0 | Max 0.3 |

Product Details:

| Minimum Order Quantity | 250 Kilogram |

| Material Grade | CW713 |

| Shape | Round |

| Usage/Application | Automotive and Hydraulic |

| Brand | SHREE EXTRUSIONS LIMITED |

| Diameter | 1 mm To 220 mm |

| Composition | As per CW713 |

| Tensile Strength | 540 N mm2 |

| Elongation | 12 |

| Temperature | 500 to 600 |

| Color | Yellow |

| Hardness | 160 HB |

| Material | Brass |

| Packaging Type | Wooden |

| Standard | CW713 |

| Astm | C67400 |

| Alloy Or Not | YES |

Precision Engineered Strength

CuZn36Al4FeMn Brass Rods are renowned for their high tensile strength, yielding up to 820 MPa. Their robust composition and reliable yield strength ( 250 MPa) make them the preferred choice for heavy-duty engineering, ensuring longevity and performance in critical automotive, marine, and industrial assemblies.

Versatile Applications across Industries

These rods are utilized in a diverse range of sectors including electrical, hardware, plumbing, engineering components, and marine environments. Their excellent corrosion resistance and electrical conductivity make them suitable for challenging atmospheric conditions and precision-engineered electrical parts.

Superior Workability and Finish

CuZn36Al4FeMn Brass Rods can be forged, machined, and shaped to precise specifications, accommodating various design requirements. Their bright, golden-yellow, or natural finishes ensure visual appeal, while the smooth surface condition eliminates concerns about cracks or splits, optimizing quality and safety for end-uses.

FAQs of CuZn36Al4FeMn High Tensile Brass Rods:

Q: How are CuZn36Al4FeMn High Tensile Brass Rods manufactured?

A: These brass rods are produced through stringent processes adhering to IS, ASTM, EN, and BS international standards. Advanced metallurgy techniques control alloy composition and grain structure, resulting in rods with high tensile and yield strengths, smooth surfaces, and precise dimensional tolerances.Q: What are the primary applications of CuZn36Al4FeMn High Tensile Brass Rods?

A: They are extensively used in industries such as automotive, marine, electrical fittings, hardware production, plumbing, and general engineering, owing to their mechanical strength, corrosion resistance, and reliable machinability.Q: When should I choose CuZn36Al4FeMn High Tensile Brass Rods for my project?

A: These rods are ideal when your application demands high mechanical strength, resistance to corrosion, and good machinability. They are particularly beneficial for components exposed to mechanical stress and aggressive environments, such as marine fixtures and precision parts.Q: Where can I source CuZn36Al4FeMn High Tensile Brass Rods in India?

A: You can obtain these rods from accredited distributors, exporters, manufacturers, suppliers, traders, and service providers across India who specialize in non-ferrous metal products and conform to international quality standards.Q: What is the process for machining and working CuZn36Al4FeMn Brass Rods?

A: With their excellent machinability, these rods are suitable for forging, turning, milling, and shaping. Standard machining practices can be applied, and the material retains excellent surface integrity, ensuring efficient fabrication and minimal tool wear.Q: How do CuZn36Al4FeMn Brass Rods benefit engineering and technical projects?

A: Offering high strength-to-weight ratios, robust corrosion resistance, and consistent electrical conductivity, these rods increase reliability and lifespan of components, reduce maintenance needs, and perform well under mechanical and environmental stress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Tensile Brass Rod' category

|

SHREE EXTRUSIONS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

marketing@shree-extrusion.com

marketing@shree-extrusion.com